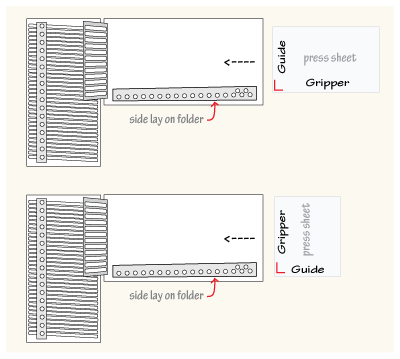

When I first saw this question I wondered why a folding machine operator would even ask it. It goes something like, “When I load my folder, where should the guide and gripper edges go?” Or, “Does it matter which way I load paper into a folding machine?” I reminded myself there is a first time for any question, especially learning a complicated subject like bindery work.