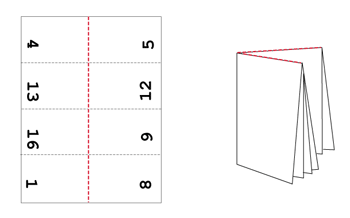

If you’re new to running 16-page signatures, you might feel a bit overwhelmed with the workload, even with an automatic stacker on a new folding machine. I know I did. Folding 16 page signatures, or any signatures for that matter, requires a lot of effort and attention to detail. There is a lot of stuff going on that you have to keep an eye on. You’ll be doing quality control for multiple folds, loading and unloading, and stacking it all neatly on a skid for the next guy in the production process.

If you’re new to running 16-page signatures, you might feel a bit overwhelmed with the workload, even with an automatic stacker on a new folding machine. I know I did. Folding 16 page signatures, or any signatures for that matter, requires a lot of effort and attention to detail. There is a lot of stuff going on that you have to keep an eye on. You’ll be doing quality control for multiple folds, loading and unloading, and stacking it all neatly on a skid for the next guy in the production process.

And of course there is the ever-present pressure of deadlines. It’s easy to be tempted into skipping a little QC work just to get the job out the door.

But thanks to co-workers and LOTS of hands-on experience, I learned some valuable time-saving habits which make signature work easy. What I’m demonstrating in the video is one of those simple habits to help reduce your operator workload and keep the quality high. It soon became second nature to me…so much so that I nearly forgot that I used to do this!

When you watch the video you see that it looks like nothing is happening. But in a short amount of time, literally seconds, you can do a quality check on most of the important factors in folding.

Although I’m using 16 pagers here on our MBO folder, you can do this folding machine quality control check on any folded piece coming off any machine.

Click the video to watch and be sure to share any comments or suggestions below. And if you like the video, share it with your folding machine operators using the social buttons above or at the left.