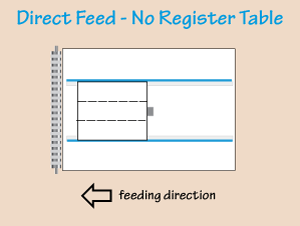

This week we have another simple thing to check to get better results fast on tabletop folding machines or on small rotary scoring or perforating machines. As with last week’s bindery video, I’m referring to the type of scoring or folding machines that don’t have a register table.

This week we have another simple thing to check to get better results fast on tabletop folding machines or on small rotary scoring or perforating machines. As with last week’s bindery video, I’m referring to the type of scoring or folding machines that don’t have a register table.

Last week we talked about how improperly trimmed or seriously curled paper will hurt the quality of the finished product coming off these machines. Of course poor paper will worsen finishing quality on any machine, even the most sophisticated. But on more complex equipment there are ways to compensate for poorly trimmed paper. With direct feed machines it’s almost impossible to compensate for bad cutting.

The simple checklist item I’m talking about today is the infeed guides. Just like bad paper, incorrectly set guides can make for bad results. I’ve seen it lead many newcomers struggle to fix a problem by adjusting everything except the thing which should be adjusted. Many new operators don’t realize just how important proper setup of the infeed guides is to getting good, consistent results.

The video below shows why attention in this area is important. Then it goes on to demonstrate a few easy ways to “square up” the infeed guides on your scoring or folding equipment. If you own or operate any Baum 714 folder, or Pierce, Rosback, Rollem, Graphic Whizard, Count Machinery, CreaseStream Mini or similar scoring or creasing machines, this video could help.

It’s not a complicated subject. But if you overlook this item, it will certainly complicate your post-press life! Click the video below to watch, and if you have any suggestions of your own, please feel free to add them below in the comments.