One of the beneficial things about an abundance of print finishing technology is that we get more flexibility in how, when, and where to finish any given job. Yet that same flexibility makes production planning more complex.

For instance, one of the questions we get from print finishers who have a mix of equipment and accessories goes something like this, “How do I determine where to perforate a job?” Their shops might have perforating capability on presses, die cutters, letterpresses, folding machines, or perforating machines. Do you decide by run length, sheet size, turnaround time, quality expectations, or cost?

For instance, one of the questions we get from print finishers who have a mix of equipment and accessories goes something like this, “How do I determine where to perforate a job?” Their shops might have perforating capability on presses, die cutters, letterpresses, folding machines, or perforating machines. Do you decide by run length, sheet size, turnaround time, quality expectations, or cost?

If we have a few years of bindery experience we tend to rely on that experience and maybe on some production rules of thumb. Some shops do it a certain way because that’s the way they’ve always done it!

Of course if your shop has limited bindery equipment available the choice is made for you. But if you’re faced with multiple solutions, there is a way to give more clarity to your production planning sessions and perhaps even answer the question outright.

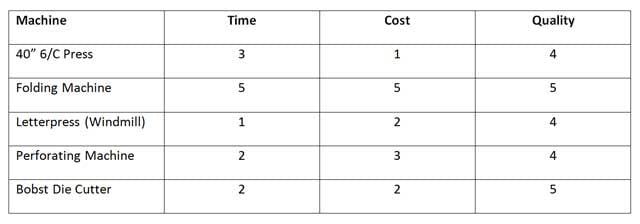

One way to do this is to create a simple decision-making matrix. (see below) Label your columns with important factors such as Time, Cost, and Quality. You can add other Factor columns that might be important such as Difficulty, Operator Experience, or Customer Preference. Then add a row for each piece of bindery equipment you might want to use. In our example we’ll use Press, Folder, Letterpress, Perforating Machine, and Bobst Die Cutter.

Assign a weighted value to each factor according to the job you want to run. For instance, let’s use a rank of 1 (low) to 5 (high) with the higher number being the preferred number. Thus for Cost, high = 1 and low = 5. For Time, fastest = 5, slowest = 1. For Quality, highest = 5, lowest = 1.

Let’s say you want to perf and fold 50,000 sheets of 8.5 x 11 20# bond to a #10 letter fold. When evaluating the overall Time and Cost, keep in mind the job has to be cut, perfed, and folded.

Here’s what a sample matrix might look like:

In this case, the folder equipped with a Micro Perforator comes out as the clear winner. Of course yours will differ according to your equipment and factors. If you don’t have a precision perforating kit on your folding machine, your Quality score for perfing on the folder might be 2 or 3. If you have a Technifold Micro Perforator you can give it a 5. If you’re running a 2/C 25” press, your cost might be a 3, and so on.

At the very least, a decision matrix will give you a great starting point for your planning discussion, even if you don’t go with the winning number. It helps you to incorporate factors into your decision-making that might be overlooked were you to rely solely on experience, custom, or an operator’s suggestion.

So the next time you’re stumped with a print finishing production problem, perforating or otherwise, try a decision matrix. There are many variations on matrix techniques which you can easily find online. Just be sure to keep yours simple enough to ensure you’ll actually use it.

Feel free to share your decision-making stories or tips below!