The first inkjet printer I purchased was a promising marvel of technology. In the first months of running a startup business, I was thrilled that I could now print a few full color letters or brochures in my own office. Then as I began running various designs, different types of paper and envelopes, along with attempts at mail merges, the luster of the new technology quickly turned into frustration.

The first inkjet printer I purchased was a promising marvel of technology. In the first months of running a startup business, I was thrilled that I could now print a few full color letters or brochures in my own office. Then as I began running various designs, different types of paper and envelopes, along with attempts at mail merges, the luster of the new technology quickly turned into frustration.

Although I had more than twenty years’ experience in the printing industry at the time, I simply didn’t know what I didn’t know. Instead of educating myself first, I found myself learning a few more things about do-it-yourself printing the hard way.

When we take on new technology such as printers and print finishing equipment designed to help us run our businesses more effectively, we buy the promise, and then trust that the rest will sort itself out. Yet even the simplest of jobs can become very complicated due to the number of variables involved. Even the professionals can be caught unaware!

Because of advances in technology, today there are all types of small businesses who do significant amounts of printing in-house.

- Greeting card and wedding invitation specialists

- Funeral homes who create and produce their own memorial service cards

- Graphic designers who print their own short runs

- Small to medium businesses who produce and mail their own newsletters, brochures and sales letters

- Boutique print shops doing letterpress and specialty work with homemade papers

Essentially they are running their own in-plant printing and print finishing operation. Once the promising new technology arrives, the education begins. Topics like ink, toner, duplexing, humidity, scuffing, register, folding, and fiber cracking, become a necessary part of the vocabulary. Many fledgling do-it-yourself printers contact us to solve one problem only to discover they have several. Most are surprised by the number of problems that can arise after the job is printed. They don’t know what they don’t know.

One funeral director said he felt uneasy presenting memorial service cards to a grieving family that weren’t folded neatly and consistently. His “folding problem” was actually the result of problems with paper selection, trimming and scoring.

A greeting card designer who printed short runs for his customers said he had a scoring problem. The samples he presented were so curled as to be unusable in any scoring machine. Clearly he had either a printing problem or a paper problem.

In both cases, the true cost of their problems will never be known. The lifetime value of lost customers is high, as is the cost of replacing them with new ones. We all know that an unhappy family member will spread the word quickly, whether it’s from a shabby wedding invitation or a flimsy memorial service card.

If you’re new to running a short-run in-plant printing operation, take heart. Here are five common print finishing areas to be aware of when planning your jobs. They’re all very easy to deal with and it won’t be long before monitoring them is second nature. But if you ignore them, it won’t be long before you deliver a product that causes problems with your customers.

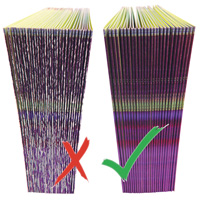

Perhaps your greeting cards, brochures, invitations or memorial service cards are not square or are folded inconsistently. Details like this make for a poor presentation, especially if your customer is paying for expensive paper or you represent a premium product.

This is a big ‘gotcha’ of which print industry insiders are well aware. The output capability of even the slowest of printers or copiers can quickly create a print finishing bottleneck.

3) Paper Cracking, Breaking, Tearing, or Curling.

3) Paper Cracking, Breaking, Tearing, or Curling. Nearly all stocks heavier than a 24# bond will benefit from creasing the sheet before you fold them.

It’s not uncommon for a complaint about folding or scoring to be a problem with trimming. This can happen when the novice printer tries to trim the job on a low-end office trimmer purchased at the office supply store. They’re perfectly fine for trimming one or two sheets here and there, but will fail miserably when trimming any type of premium quality print job. They will also never keep up with the volume of even the smallest printing operation.

This is another common problem. Don’t be a cheapskate when it comes to investing in paper. Again, this is doubly true if you are offering a premium product. Delivering a light weight stock when your customer is expecting a beautifully printed, keepsake-style piece on card stock will cost you. Paper should always match customer expectations.

You’ve made your investment in good equipment. Be sure to invest some time in honing your post-press skills. After all, why bother to print it if you can’t finish it? In short order, the level of your finishing expertise will match the print quality of that brand new laser printer.

Have a question or problem with a print finishing job? Then take advantage of our decades of print finishing experience. Add your question in the comments section or use the Contact Us form.