Generally speaking, folding book weight stocks is a relatively easy folding machine task. Yet a new operator, upon encountering paper that is lighter than he is accustomed to, might find himself scratching his head wondering why fold consistency is suddenly a problem.

Generally speaking, folding book weight stocks is a relatively easy folding machine task. Yet a new operator, upon encountering paper that is lighter than he is accustomed to, might find himself scratching his head wondering why fold consistency is suddenly a problem.

Folding light weight paper has an extra dimension of difficulty because of the thickness of the stock itself. A 40-60# coated or uncoated book paper can be less than .003” thick with varying degrees of stiffness. These types of stock are typically found in web press shops and in binderies that do work for web printers.

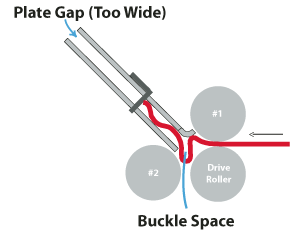

The thinner a stock is, the easier it is for it to buckle and distort in various spots as it moves through the folder. The friction of moving into a fold plate can be enough to buckle or collapse the sheet in ways that make it look like the fold itself is actually varying. (The diagram upper right illustrates the concept.) Registering the sheet on the infeed table also gets trickier as the stock gets thinner.

Here are seven simple tips to overcome these and other minor problems associated with folding thin paper.

1) Decrease the buckle plate gap and the buckle space to compensate for the thinner paper. Most new machines have an easy way to do both while many older machines only have an adjustment for the buckle space. Basically the buckle space adjustment is a way to move the lower portion of the plate away from or towards the fold rollers, thus changing the amount of space available for the sheet to buckle. The diagram above shows a plate gap and a buckle space that are too big for the paper being run.

The buckle plate gap should be adjusted to the minimum gap for very light papers. Sometimes you can cheat on the old folders by taping sheets of cover stock to the inside bottom of the fold plates to change this gap. It’s a little tricky to accomplish but if you’re careful, it can help a lot. (We might show this in a future article.)

2) Be sure the moisture content is correct. Higher moisture content adds stiffness to paper, which in turn aids accuracy in folding. This is more of a preventive measure in that you want the paper you are running to be acclimated correctly before, during and after printing. It should be run in an environment within the temperature and relative humidity range recommended by the paper manufacturer. Doing this ensures optimum moisture content by the time it reaches you at the folding machine.

If the paper is dry, it’s possible to increase the moisture content of paper by storing it in a moister environment for a time. The downside is that if the sheets are flat, you might create another problem such as wavy edges. (On the other hand, if your sheets already have tight edges [curl] doing this will actually reduce the tight edges.)

3) Lay out the job so the fold is against the grain. This puts the grain running the long direction of the sheet and provides a little extra stiffness to prevent it from buckling inside the plate.

4) Add stiffness to the sheet by lightly hand creasing the leading edge of each lift as you load the machine. If there is already a curl in the sheet, crease away from the curl so it also flattens out the sheet. The crease should be just strong enough to give the sheet extra stiffness without showing up in the final folded piece.

4) Add stiffness to the sheet by lightly hand creasing the leading edge of each lift as you load the machine. If there is already a curl in the sheet, crease away from the curl so it also flattens out the sheet. The crease should be just strong enough to give the sheet extra stiffness without showing up in the final folded piece.

Small sheets may only need a couple of creases. Add more for larger sheets. Crossing the creases (diagram lower right) is helpful on larger sheets or very limp sheets.

5) Use the lightest and fewest number of side guide marbles possible. Too much weight on the sheet can cause it to buckle up within the side guide which in turn causes folding and wrinkling problems.

6) Run the folder slower than you would with heavier weight papers. In many cases this is all you really have to do, especially if you’re only moving to a slightly thinner stock, such as from a 60# to a 50#.

6) Run the folder slower than you would with heavier weight papers. In many cases this is all you really have to do, especially if you’re only moving to a slightly thinner stock, such as from a 60# to a 50#.

7) Be sure the fold rollers are precisely adjusted according to your folder manufacturer's directions. Folding problems will appear more often on the lighter papers when the machine isn’t quite up to par or if you’ve gotten a little careless in your setup routine.

The good news is that once you have the first fold out of the first fold plate, you’re now working with a much thicker sheet. Folding should now be relatively normal as you move through the subsequent fold plates and right angle sections. With experience, you might even find that you prefer to fold light weight papers.

Here are two related blog articles that also talk a little about folding light weight papers.

Forgotten Fold Plate Adjustments

Feel free to share your experiences, comments and suggestions about folding light weight papers below.