Bindery equipment seems bound by the universal truth that the flatter the sheet, book, signature or brochure, the easier the processing, whether it’s folding, saddle stitching, gluing, perfect binding, mailing or any of dozens of other post-press and print finishing operations.

On the folding machine, a flatter folded product will stack better in the delivery, which means higher production speeds. A spongy brochure or signature that pops open will slow you down in both setup time and run time. Although there are presser/stacker delivery units available to run inline with most folding machines, the return on investment may not work out if you don’t do a lot of long runs.

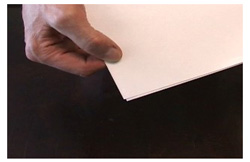

Here’s a simple technique sent in by Reno Cyr of JS McCarthy Printers, which turns the slitter shafts into effective pressing rollers for those occasions where you really need some help with a flatter fold. First, gather enough pull-out wheels (gripper rollers) to cover the width of the folded piece. Be sure they’re all the same type and in good condition, then snug them together as shown in the photo upper left. Check slitter shaft pressure, run 25 sheets and check the sheets for marks.

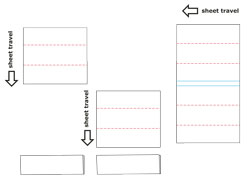

If there are no marks, increase pressure as needed, making sure you check for marks after every adjustment. According to Reno, the amount of pressure you can use will vary with each job. The photo lower right shows a double gatefold on 80# C2S cover. Both stacks are in 25’s—one has been flattened with this method, the other one delivered without pressing.

The result: substantially flatter lifts, easier handling, faster folding machine speed and more pieces packed per carton. Reno also claims that he’s been able to use this method to fix those occasional troublesome jobs that just won’t fold quite squarely. This he accomplishes with some trial-and-error adjustments on the pressures from side to side, essentially forcing the folded piece back into a square position.

There is one caution to this method. Adding additional pressure on the slitter shafts will wear the shaft bushings and springs faster than normal. However, if you are doing even a moderate volume of folding work, this is a reasonable tradeoff. You spend a few extra dollars on replacing these items a little ahead of schedule (a relatively simple fix) in exchange for a big return with the benefits mentioned above.

You also want to resist the temptation to use extra pressure on the fold rollers. Yes, this will flatten a piece to some extent, but the downside is that you prematurely wear 6 fold rollers and all their bushings. That’s a repair that can run into a couple thousand dollars. We’ve seen more than one operator over the years who would use a single sheet in all the fold roller calipers no matter what job they were running. Everything was flatter, but the tradeoff is the premature wear plus a higher incidence of folding ‘problems’, usually fixed by simply adjusting the fold roller pressures correctly.

The bottom line is that flatter equals higher productivity. If you do lots of signature work, we encourage you to research a presser/stacker delivery. Not only will you get higher speeds on your folding machine, you can usually accomplish it with a single operator instead of two. So the return on investment can be quicker than you might think. Today there is plenty of good used equipment on the market and lots of great new bindery equipment. In the meantime, you can always fall back on this clever bindery trick.