This week we have a video tip to help folder operators with the loading of continuous feed folding machines. Continuous feeders are easy to learn and operate. Yet I’ve seen novice and experienced operators alike suffer big production losses because they were lax in their loading technique.

This week we have a video tip to help folder operators with the loading of continuous feed folding machines. Continuous feeders are easy to learn and operate. Yet I’ve seen novice and experienced operators alike suffer big production losses because they were lax in their loading technique.

You can definitely call this an 80/20 problem. Here we have a small, seemingly unimportant detail that’s easy to overlook. Suddenly it has an oversized and negative impact on production. It can cause late deliveries and can affect the overall quality of a job.

The secret to high-yield production on any bindery equipment is to keep it running continuously. Anything that stops the folder thus prevents maximum yield. If you’re habitually running a machine that stops for doubles, or any other reason, you will never get the production you should be getting.

In my experience, one of the main reasons for folder stops is double sheets at the feeder. This has two common causes:

- Paper isn’t adequately fanned and/or separated and

- The paper itself is stuck together

I’ll wager that most operators have found themselves with a fully loaded machine which is stopping frequently for doubles. At this point you have two time-wasting choices:

- Suffer through the doubles…and there could be LOTS of them

- Unload the machine, jog the sheets, reload and start again. Both scenarios take a lot of time.

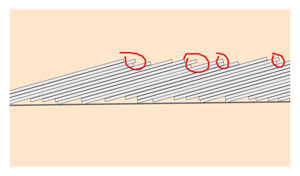

In the video below, using our MBO folder, we share four tips to help your loading technique. If you’re a new operator or you’re struggling with loading folding machines, be sure to watch. It’s important to develop your technique so you have consistent loads on the feeder. This ensures your folder will run at a continuous, non-stop pace. You’ll produce more work with less effort. And who wouldn’t want that!

If you have a folding machine loading technique to share, be sure to let us know below. And use the social buttons to share this video with your colleagues.