It’s been said that the best way to learn a subject is to teach it. I discovered this to be true when as a bindery supervisor it fell on me to train new folding machine and bindery equipment operators.

I had no training as a teacher. My training as an operator was a degree from TTWU…Thrown to the Wolves University. I was however, fortunate to have countless valuable conversations with great equipment mechanics and experienced co-workers. From that hodgepodge I derived my own effective way of working.

How then, was I to transfer my own hard-won knowledge to my slack-jawed folding machine trainee? There he stands, second-guessing his decision to learn about the incomprehensible bucket of bolts before him. His only concern is how soon a pay raise kicks in after he touches the start button.

Here I stand, surrounded by jobs spewing from the presses in my direction. Thoughts of impending doom take over as I ponder deadlines combined with this new training task. “Can he even jog a lift of paper? Will he show up for work tomorrow? He’ll probably quit as soon as I get him trained. Maybe I’ll just stay all night and do it myself…”

My first useful thought was to ask the fellow to read the folder’s instruction guide. But there was no step-by-step methodology. It would generate more questions than it answered. But it turned out that my own way of working on folders held an answer. When I got my private pilot’s license a few years later I learned that airline pilots use “my” technique. I figured it out quite by accident and had been using it for years.

My technique actually has a name in the aviation world. It’s called “flow.” As a student pilot I was taught to use checklists for the various phases of flight. We were also encouraged to memorize everything we could about the aircraft we flew. At first I felt like most new folder operator—overwhelmed and confused. There are hundreds of checklist items for the aircraft.

Then I started to use the same technique with an airplane that I did with a folding machine or saddle stitcher. In the bindery I’d pick a logical starting point on the machine such as the feeder. Then I’d work my way through to the delivery until everything that needed adjustment was checked or adjusted. At that point I was ready to run a sheet.

In the aircraft cockpit, I’d start a scan at the floor, move up to the instrument panel, and then overhead. Again, every item was either checked or adjusted as needed. Then I’d use a checklist (as required) to be sure I missed nothing. Things became faster and easier. I was no longer overwhelmed.

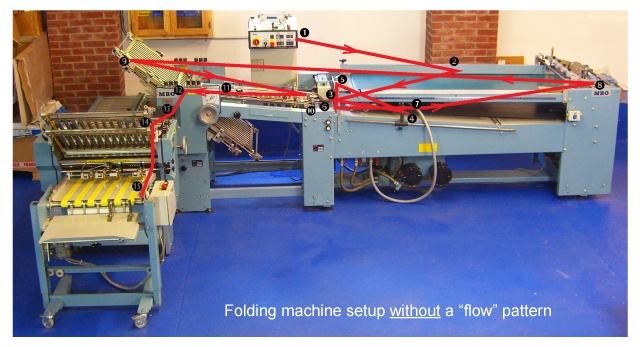

The two pictures below illustrate the simple concept and how it applies to bindery equipment.

In the first photo, I diagrammed the setup steps in the order they’re presented in our MBO B123 instruction manual. In all fairness, most manuals are not designed to be a step-by-step guide. Workflows vary so much around the world that it’s hard to say “Do 1, 2, 3, etc.” and have it come out right. Manuals show how each component of the machine works so you have a basic understanding of how to set it up. I’m merely using the manual to show how a lack of flow will make it harder to learn, train, and set up any machine.

Here’s the order of items presented in this particular manual (without a flow pattern):- Suction length and sheet gap setting

- Side lay

- Feeder tongue

- Tail wheel (back of sheet)

- Sheet supports on upper feed board

- Air blast and sheet separation

- Sheet guides on lower feed table

- Belts and straps around drum

- Fold plates

- Caliper

- Register Table

- Fold Roller Calipers

- Slitter Shafts

- Right angle sections

- Stacker/Delivery

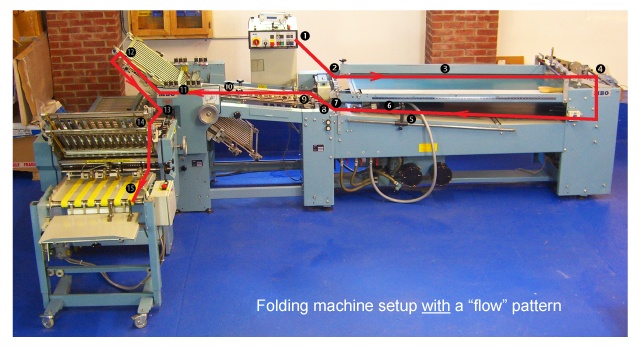

Now here’s how you might set up the folder with a flow pattern:

- Suction length and sheet gap setting

- Sheet supports on upper feed board

- Side lay on upper feeder board

- Belts and straps around drum

- Tail wheel (back of sheet)

- Sheet guides on lower feed board

- Feeder tongue

- Air blast and sheet separation

- Double sheet detector

- Register table

- Fold Roller Calipers

- Fold Plates

- Slitter Shafts and appropriate tools

- Right angle sections

- Delivery

OK, which one of these is easier to teach, to learn and to remember? I’m sure you picked the second photo. Yet your own setup routine, if diagrammed, will probably vary. As long as it’s intuitive and easy to remember, it can also help you train others. That’s the beauty of flow.

Your flow should work well for the way you think and work. For instance, when you reach the fold roller calipers you have a choice. You can set the first section calipers and then move on to the fold plates. Or you can set all the calipers including the right angle sections. After all, you’re thinking about the folded sheet and what’s required for each roller. I always preferred to set all the calipers at this point but you might do it differently.

The same goes for fold plates. It might be easier to set all the fold plates in all sections since you’re already thinking about the whole fold sequence anyway.

Flow follows a logical, natural progression through the machine. It should be intuitive so you don’t have to think too much about how the task is getting done. Even with modern, automated equipment, there will be a natural flow you can utilize to make setup easier.

When you use flow, you are physically going past each adjustable item on the folding machine and checking or making adjustments. It’s very hard to miss something this way. On the other hand if you’re trying to remember 100 pages of instruction manual, you might forget a few things. Flow helps our brains to simplify and grasp the complex.

To recap, here are some important advantages of using flow:

- It prevents you from overlooking important items

- It improves quality because you won’t forget anything

- It acts as an internal checklist without actually having to have one

- It decreases your setup time

- It makes training easier

Although we’re talking about folding machines today, flow can be used on any bindery equipment, from the simple to the complex. It can also be used to improve the actual operations and ergonomics of print finishing work. More on that coming in future articles!

As always, we welcome your comments and stories below. If you liked the article don’t forget to share using the social buttons above.