As a bindery novice, folding machines with pile feeders made me want to pull out my hair, or on a really bad day, someone else’s hair. The bigger the pile of crumpled paper around the folder, the further away my co-workers would stay. Except for one friend who intentionally waited until I reached the breaking point. With a Cheshire grin he’d slap me on the back and say, “Hey, Andre, how’s it going?!” In time, I learned a few things about pile feeders which didn’t keep my friend away, but they kept the folder running smoothly.

Modern pile feeders with electronic sensors are much easier to run than the old mechanical mechanisms. But there are still plenty of the older pile feeder machines out there. Some of these tips will help no matter which type of machine you are using.

Read the folding machine instruction manual! You might be surprised at what you find. I’m guilty of not reading manuals even though I learn something new every time. Most of you won’t do this but I’ll put it on the list anyway!

If your machine has a vacuum adjustment, use it. In almost all cases, vacuum should be the minimum required to pull the sheet into the register table. No more, no less.

Are you getting correct, even separation of the top few sheets? It should be about 8-12 sheets or so, depending on the manufacturer’s suggestion, and it should be separating nearly the full length of the sheet. Again, read the manual as this will vary. There will probably be a drawing to illustrate what the pile should look like when you have proper separation. Or perhaps you figured out the best sheet separation scenario for your particular folder.

Are you getting correct, even separation of the top few sheets? It should be about 8-12 sheets or so, depending on the manufacturer’s suggestion, and it should be separating nearly the full length of the sheet. Again, read the manual as this will vary. There will probably be a drawing to illustrate what the pile should look like when you have proper separation. Or perhaps you figured out the best sheet separation scenario for your particular folder.

Whatever it is, keep this sight picture in mind. The trick is to make the pile feeder work for you to maintain that picture with each upward lift of the pile. In other words, as your folder is running, the top of the pile should always look like your picture. The photo above right, from a Baumfolder manual for a Baum 18, is one example. If you find the “picture” changing, then you need to make adjustments until you can maintain that picture. It’s the only way to avoid doubles and mis-fed sheets.

Be sure the pile stops the correct distance from the vacuum wheel. This is usually about 1/2” or a finger thickness away. Your manual will tell you.

Before switching on the air, let the machine raise the pile the final couple of inches. Repeat this step every time you put a new lift in the feeder, and then check that it’s stopped at the correct point before running. If not, take the time to lower the pile and re-adjust the pile height mechanism. Then let the machine raise the pile again to check that it’s now in the right spot. Many operators think, “I've already set the machine so why do it again.” Then they load up and try to run without checking to see where the pile stops. This, in turn, leads to poor feeding, double sheets, and immense frustration.

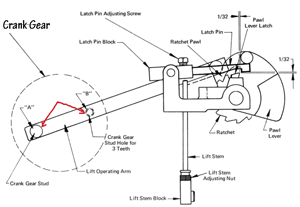

For pile feeders with a ratcheted lifting mechanism such as those on older Baumfolder machines, check that you are using the best hole in the crank gear. (Two holes shown in this diagram from Baumfolder) The inner hole will raise the pile in smaller increments (for light stocks) and the outer hole will raise it in larger increments (for heavier cover stocks.)

For pile feeders with a ratcheted lifting mechanism such as those on older Baumfolder machines, check that you are using the best hole in the crank gear. (Two holes shown in this diagram from Baumfolder) The inner hole will raise the pile in smaller increments (for light stocks) and the outer hole will raise it in larger increments (for heavier cover stocks.)

Running in the outer hole on light materials can cause too large an advance, followed by double sheets. Running in the inner hole on heavy stocks creates too small an advance and in turn, erratic feeding. I learned this the hard way because I didn’t bother to read the manual…for a very long time!

Use wedges—carefully. Ideally the pile you load should be perfectly flat from the top sheet to the bottom. The reality is this rarely happens. It can change shape from one pile to the next, and from top to bottom, for various reasons.

- Curl can come and go, and you have 4 edges that can curl up, down or remain flat. If the job is cut several-up from a large sheet, it can get quite interesting. Severe curl may require that you de-curl the sheets before folding. (We’ll talk about that in another article.)

- The amount of air in the sheets varies with an operator's jogging technique. One side of a pile may be higher than it was in the first load, so an adjustment will be needed.

In these cases use the wedges to make the top of the pile flat. Note that as the pile diminishes you need to adjust the wedges to maintain that flat profile. Of course you may sometimes run the pile with a slight up curl or down curl just because it feeds better. In that case use the wedges to maintain that profile. It sounds like a lot of work, but it’s not once you do it a few times.

You really want the folding machine to do all the work for you. With these extra habits built in to your work routine, your folder will be happy to oblige. Sorry to say that I don’t think there is anything to eliminate the co-worker who likes to break your chops. That fellow comes standard with every printing company.

As always, you’re invited to share your tips or experiences below!