Learning to run a folding machine can be a little overwhelming, especially if you’re thrust directly into a bindery department production environment without much training. I remember my first day on the job being shown the antique Baum folding machine and thinking, “Seriously now…that thing actually folds paper?”

To me the old Baum looked like something from my grandparent’s generation that should be belching steam or smoke. Maybe it even required a team of horses. It was an oily contraption of dangerous gears and moving parts seemingly held together with belts, chains and the occasional piece of wire or tape.

Fortunately, I must have had what author Shunryu Suzuki calls the beginners mind. “This does not mean a closed mind, but actually an empty mind and a ready mind. If your mind is empty, it is always ready for anything. It is open to everything. In the beginner's mind there are many possibilities. In the expert's mind there are few." An expert would have scrapped the folder whereas I somehow managed to learn how to be a folder operator, and in doing so, learned many valuable lessons.

Throughout the first year of trauma…I mean training…I had several “aha” moments of enlightenment, where things clicked for me. With the perfect clarity of hindsight, here are 5 tips I’d like to pass along to the novice folder operator.

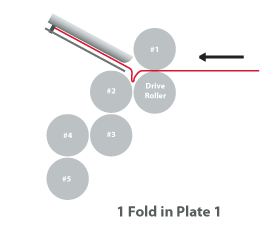

1) Think of the fold roller system as a ‘drive’ or ‘push’ system rather than a ‘pull’ system. Intuitively the novice operator will look at the fold rollers in motion and think that the rollers are pulling the sheet through. After all, if you stick you’re fingers in there while it’s running it will obligingly ‘pull’ your fingers or whatever else you’re holding into the machine. (Please don’t do this.)

But that notion is wrong. The fold rollers are actually driving or pushing the sheet through the machine to make the fold. That is the very nature of a buckle folding machine—the leading edge of the sheet hits the fold plate stop and the trailing edge must then be pushed through until the sheet buckles for the fold to happen.

If you want to demonstrate the fact that ‘pushing’ is more important, set the machine up for a 4-page fold in plate #1 and put 3 sheets in fold roller caliper #1. Run 1 sheet. The first half of the sheet will go into the first fold plate and stop right there, with the fold roller whirling away on top of the sheet. Once you re-set the first fold roller to 1 sheet, it will snappily push the sheet toward fold roller #2 to finish the fold and then onward to the delivery.

If you want to demonstrate the fact that ‘pushing’ is more important, set the machine up for a 4-page fold in plate #1 and put 3 sheets in fold roller caliper #1. Run 1 sheet. The first half of the sheet will go into the first fold plate and stop right there, with the fold roller whirling away on top of the sheet. Once you re-set the first fold roller to 1 sheet, it will snappily push the sheet toward fold roller #2 to finish the fold and then onward to the delivery.

Yes, there is indeed a pulling component at work as the sheet travels through the fold rollers. But it is the push on the trailing edge of the sheet that really matters when setting fold roller pressure.

2) Talk to your folding machine mechanic when he comes in. Don’t disappear into the break room. After struggling with folder setup for several weeks, I risked what I thought would be great embarrassment and asked our mechanic some ridiculously basic questions. He patiently drew me some pictures and explained exactly how the fold rollers worked which prompted my first big enlightenment as described above.

From then on I always asked any visiting bindery mechanic all the questions I could think of. I even kept a list of questions ready for the next time they called. Most of these guys have many years of valuable bindery experience that they are happy to share, but they can’t read your mind. You have to ask.

3) Read the manual. You will probably learn something. The longer you put off reading the manual, the more important and productive will be the discovery you make. I confess I used to hate running some of the pile-feeder folding machines. For a few years I struggled to get consistent feeding. Then one slow day I read the manual and discovered a little 30-second adjustment for that particular machine which made all the difference. Duh…

4) Always make sure you get the folder to feed smoothly and consistently. (See how these are all linked?!) If it’s not feeding well, it probably won’t fold well even if you perfectly set the fold rollers and fold plates. Poor feeding ensures plenty of jam ups in the delivery and in the feeder which in turn ensures a rising level of frustration.

5) Take a folding class. Manufacturers, dealers and mechanics often have regularly scheduled classes available. Ask around, or have your mechanic do some in-house training. It’s money well spent.

My early training was mostly on-the-job with instruction from various co-workers and mechanics. I also got a part-time night job at a trade bindery running folders which proved invaluable. Thank God my boss at the bindery (the owner) was patient with my endless problem-solving questions. By that I mean that I was endlessly having problems because of my inexperience and endlessly nagging him for the solutions!

So if you can take a class or get instruction early on, it will make your life as a folding machine operator much easier. If your company won’t pay for it, (and they should if they are wise) consider doing it on your own. It’s a skill that won’t disappear.

If you have any “aha” moments that might help a beginner, feel free to leave them below. And for you beginners, be sure to download How to Get the Most from Your Folding Machine Operators and check out the Free Resources page on our site for other helpful folding machine tips.