These unsung folding machine accessories go by several names including pull out wheels, gripper rollers, transfer wheels, gripper bosses, register wheels, drive rollers, and probably more we aren't aware of. They serve a few important functions on folding machines and most other types of bindery equipment.

As their various names imply, they serve to:

- move the paper from one section of the machine to another

- keep the paper flat and straight while scoring, perforating or cutting operations are done

Modern bindery equipment has sheet calipers that automatically set the proper gap so most of the time the pull out wheels are an afterthought. However, certain precision finishing operations such as micro perforating (anvil style) and creasing sometimes require adjustments of the gap (pressure) on the slitter shafts that hold the pull out wheels. Sometimes this causes the pull out wheels to lose grip on the sheet, which in turn can lead to inaccuracy in registration.

Note: in some cases the use of pull out wheels does more harm than good. Click Here to read tips about this subject in a previous Bindery Success Blog article. In other cases you’ll find that you do indeed need the proper grip on the sheet to maintain accuracy in your perfing, creasing or cutting operation.

The problem becomes, “How do I compensate for the various outside diameters of the tools and pull out wheels that are being used on the shaft?” It would be nice if the pull out wheels (or better yet all the tools) had a variable outside diameter. Why? Well think about having 2 devices on the shaft, each with a different outside diameter. Common sense tells us that this could easily cause problems in a variety of ways. But we’ll use a little math example to show you how.

(If math makes you glaze over, skip to the next paragraph!) Let’s use a diameter found on many popular folders: Let’s say the pull out wheels are 58mm, or 2.283 inches in diameter.

Pi x diameter = circumference

3.1415 x 2.283” = 7.17”

For one revolution of the shaft the sheet travels 7.17”. Now let’s say the tool on the shaft has a 58.5mm outside diameter (2.303”.)

3.1415 x 2.303” = 7.23”

That translates to 7.23 – 7.17 = .060” (1/6”) difference in sheet travel (between the tool and the pull out wheels) for each revolution of the shaft. So, if for instance, your sheet is 17” long, you need about 2.3 revolutions of the shaft to move the sheet through completely. 2.3 x .060” = .138” (more than 1/8”) difference in sheet travel between the tool and the pull out wheels.

In other words, by the time you get to the tail of the sheet, the tool wants to push the sheet more than 1/8” further along than the pull out wheels (which happens to be a good scenario for ripping.) The longer the sheet, the greater the difference.

It’s obvious then how this difference in OD can affect the consistency and accuracy of the sheet travel. This can also be the source of such problems as nicking, tearing, curved or ‘tailed’ perfs and scores.

As the sheet gets smaller, the problem diminishes. And the smaller the difference in outside diameters, the less likely there is to be a noticeable problem.

As the sheet gets smaller, the problem diminishes. And the smaller the difference in outside diameters, the less likely there is to be a noticeable problem.

But when the problem becomes noticeable, many operators find themselves using tape on the pull out wheels, or substituting other tools with different outside diameters to use as pull out wheels in an attempt to get the proper grip. In reality what they are trying to do is make all the outside diameters the same.

If you’re struggling with such a problem, you might want to consider a slightly different pull out wheel available from Technifold. It has slots for two gripper bands and we’ve discovered that a good workaround to this diameter issue is to install gripper bands with different diameters. (photo left)

The blue band shown on the o

utside edge has a larger outside diameter than the black band. Both bands can also be removed to give you a third diameter to work with.

utside edge has a larger outside diameter than the black band. Both bands can also be removed to give you a third diameter to work with.

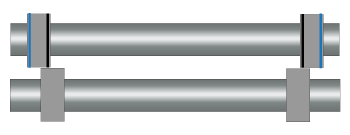

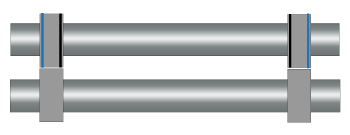

For normal use, offset the rollers so that just the black band (normal OD) is riding above the lower roller. (diagram upper left) If you have to open up the gap on the shafts and you find the pull out wheel no longer grips the sheet, then slide the upper roller over so the blue band (larger OD) is now active. (diagram lower left) If you have to narrow the gap, simply remove both bands to get a smaller OD.

We have these available for the following folding machines, including 2 diameters of gripper bands:

- Heidelberg Stahl 25mm and 35mm shafts

- MBO 30mm and 35mm shafts

- Horizon 20mm and 30mm shafts

- MB 20mm shafts

- Shoei 35mm shafts

- Rosback scoring machines (one size fits all)

It’s not the perfect solution to this problem, but it will give you a lot more flexibility when you are faced with it. If you are interested, simply fill out the Contact Us form and we’ll get back to you within a few hours the same business day.