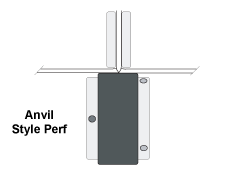

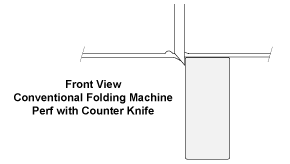

There is no doubt that our Technifold anvil-style perforating systems deliver a cleaner, flatter product than conventional folding machine rotary perforating systems (illustrations, right.) There is less distortion of the sheet and it’s possible to safely get more teeth per inch (tpi) with the stronger double-bevel perf blade typically used in the anvil method.

There is no doubt that our Technifold anvil-style perforating systems deliver a cleaner, flatter product than conventional folding machine rotary perforating systems (illustrations, right.) There is less distortion of the sheet and it’s possible to safely get more teeth per inch (tpi) with the stronger double-bevel perf blade typically used in the anvil method.

While the anvil method of perforating is simple, it’s one of the more precise operations you might do on the folding machine. The concept is this: a perforating blade runs on top of a softer cutting anvil. Ideally the blade barely touches the anvil with just enough pressure to perforate the sheet as it passes through.

But we’re dealing with machinery and there are several items that can impact how uniformly the perf blade and anvil work together.

But we’re dealing with machinery and there are several items that can impact how uniformly the perf blade and anvil work together.

- Shaft bushings or bearings can wear out

- Shafts can be slightly bent

- Springs on the slitter shafts might be weak

- Perf blades and anvils, along with their holders, may not be perfectly concentric

- Operators might rush the make-ready on a perf job

Any one of these can introduce an up-and-down action on the blade or anvil which means part of the sheet might not perf all the way through or it might cut too deep, or both!

Here are 6 tips to improve your perforating results as well as get longer life from the perf blades and cutting anvils.

- If you are using blade and anvil holders that screw together, be sure they are facing the correct way on each shaft to prevent loosening. For instance, the Technifold Micro Perforator or Multi Tool should be installed so that the allen screw on the top shaft holder is facing towards the operator. The allen on the lower shaft holder should face away. (photo left)

- If you are using blade and anvil holders that screw together, be sure they are facing the correct way on each shaft to prevent loosening. For instance, the Technifold Micro Perforator or Multi Tool should be installed so that the allen screw on the top shaft holder is facing towards the operator. The allen on the lower shaft holder should face away. (photo left)

- Give your slitter shafts a quick check up to be sure all bushing, bearings and shafts are in top notch condition.

- Use a little finesse when setting up the perforating job by borrowing this technique from operators of die cutting machines. When a die cutter is set up, one of the first steps is to remove nearly all the cutting pressure. Pressure is then gradually added and a sheet is checked for cutting. More pressure is added and another sheet is checked. This process is repeated until the sheet is cutting 80-90%. Final cutting adjustments are made by carefully adding make-ready shim tape behind the die until the sheet cuts fully. (It's greatly simplified, but you get the general idea.)

We can adapt this practice to perforating on the folding machine. Start by backing off pressure so the perforator blade is not touching the anvil. Then run a sheet to check cutting and position. Add a bit more pressure and check another sheet. Repeat the process until the perf tears evenly and cleanly from front to back. (On the folder we don’t have the option to add shim tape for the final adjustments.)

Once you get one good sheet, run 5-10 sheets and check the perf once again. If needed, add a slight bit of pressure and re-check. Once you get 5-10 sheets running cleanly, run about 50 sheets and check once again. If it is still cutting cleanly, you should now be set to run the job.

This technique will give you just the right amount of pressure and will keep the perf flat and clean. A hurried make-ready with too much pressure will give you a perfed sheet with an unsightly groove and may actually weaken the sheet or even tear it completely. Then you’ve got to start again with a clean spot on the anvil and a repeat of the make-ready process.

- Be sure to check the perf regularly as you run the job.

- If you have a paper jam or a double sheet runs through the folder, stop and check the perf. These mishaps can upset the balance you initially achieved in setting up the machine. A paper jam can also leave bits of paper wedged in the perf blade teeth, which can prevent proper cutting. You’ll want to carefully clean those from the blade.

- Click Here to view a technique for positioning the set screws on all perforating tools and pull out wheels. It may or may not make a difference, depending on the tolerances of the tools you are using. We’ve found that it does indeed improve results in enough cases that it’s worth adopting as a standard make-ready practice.

You’ll find that just a little bit of care and finesse will make a big difference in your perforating results. An added bonus is that your perf anvils and blades will last much longer. In all likelihood it will take longer to read this article than it will to implement a careful perf setup procedure.