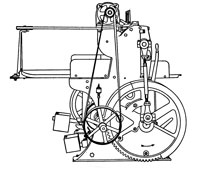

Here’s a challenge. Check out this list of tips about caring for your guillotine cutter, and then guess when they were first published. I’ll reveal the date below but resist the temptation to cheat by scrolling down.

"A man is known by the condition of the machine he keeps,” claims our cutting expert. When some simple practices become habit, the end result is better performance and productivity on your guillotine cutter (or any piece of printing or bindery equipment.) Call it old-fashioned, but I believe there is satisfaction and reward in a job well done. If you demand your personal best each day of your own accord, the rewards are even greater. So here goes:

"A man is known by the condition of the machine he keeps,” claims our cutting expert. When some simple practices become habit, the end result is better performance and productivity on your guillotine cutter (or any piece of printing or bindery equipment.) Call it old-fashioned, but I believe there is satisfaction and reward in a job well done. If you demand your personal best each day of your own accord, the rewards are even greater. So here goes:

- Keep the knife sharp. It’s probably the best investment you can make in the care of your cutter as well as its productivity and quality.

- Oil every hole and place required. New machines have automatic oiling systems so this is not such an issue any more. Oiling older machines was a job that took a few minutes, and you do not want to skip a spot because it’s hard to get to. Lack of lubrication will shut down or even ruin an older guillotine cutter.

- Oil with intelligence, not just with an oil can and oil. Wiping oil on the knife bar or oiling the jackscrew? Don’t get sloppy and let it drip all over the cutting table or the floor. If an oil spot calls for one or two drops, make it one or two drops.

- Keep the machine and work area scrupulously clean. As a mentor of mine was fond of saying, “A clean machine is a happy machine.”

- Learn by heart the operating instructions. Ask if you do not understand. "Any operator who does not understand the adjustments of the machine he operates has but partly learned his trade."

- Have a definite, fixed time to oil and clean the cutter. There is no doubt that if you do not schedule a task, it probably won’t happen. Make this part of your routine at the start and end of a shift so it becomes a habit that needs no scheduling.

- Keep the machine always in adjustment. It’s common sense. You don’t want to operate a cutter that has something out of adjustment or that has a seriously worn part such as bearings, brakes or knife gibs. The potential for machine damage or personal injury is simply too great.

- Don't allow knife to sink into the cutting stick, only deep enough to sever the bottom sheet. Take your time to do this correctly when installing a new knife. Done right, you won’t have to make adjustments again until you put a new knife in, even on the older cutting machines.

- Never use more clamp pressure than necessary. Often neglected, setting the correct clamp pressure ensures an accurate cut from top to bottom of the lift of paper. With computerized equipment, you can make a note and have the machine remind you of the correct pressure when you return to a job. The correct lift height is another factor that goes hand-in-hand with clamp pressure. On the old machines, excess pressure also reduced the force available for cutting so it was important to find the right balance.

- Use the correct wrenches and tools. These are usually supplied with the machine for a reason. If you see an operator using a monkey wrench or something similarly inappropriate, you want to step right in and stop it!

My favorite suggestion is this: Use talcum powder, french chalk or powdered boracic acid dusted on the table to make the stock handle easier. This was obviously back in the day before air tables and silicone spray and no, it does not apply today!

Believe it or not, these useful tips are nearly a hundred years old and were first published by Niel Gray in 1918 in his primer, Paper Cutting Machines. Despite the enormous advances in technology, some of the old stuff is still good stuff since our new cutters use the same basic cutting technology.

These very same ‘suggestions’ were passed on to me in my bindery apprentice days and I suspect they will continue to serve operators well for another century. As always, we'd love to hear your experiences below.