Trimming a folded piece two or more up is a great way to increase folding machine productivity. Yet the very act of trimming the pieces to their final size is a process that sometimes presents challenges.

Trimming a folded piece two or more up is a great way to increase folding machine productivity. Yet the very act of trimming the pieces to their final size is a process that sometimes presents challenges.

One of these challenges arises when there is trim between the units required because of bleed. The standard bleed is typically 1/8” so if 2 units are to be trimmed you end up with a 1/4” piece of waste to trim out.

As we all know, paper and image sizes conspire at times to rob us of the “standard” bleed; in other words we try to jam too much image on too little sheet. The result is miniscule bleeds, tough enough to handle on the guillotine cutter but even harder to work with on the folder.

When you install a rotary trimmer on a folding machine, consisting of upper and lower knife sets, you need to consider two things:

1) How to keep the waste trim from wrapping around the lower shaft and

2) how to keep the waste from shooting on to the delivery table.

All the major folder manufacturers offer lower waste deflectors (also called waste strippers) for the lower shaft and upper waste deflectors to prevent the trim from entering the delivery table.

For most jobs the stock OEM deflectors will work just fine. Most of them can be adjusted to the width being trimmed, or very close to it.

In many cases (such as with our Multi Tool) you might find you don’t need an upper waste deflector at all, depending on the stock, the width of trim and the type of cutting knives and counter knives being used. If you can get away with it, leave it off; it’s one less thing to cause paper jams.

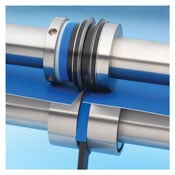

When you are faced with trims too narrow for your deflectors, there are a couple of things you can do. Our Multi Tool waste strippers are available in 3, 4 and 5mm widths (for trims of approximately 1/8”, 3/16” and 1/4”) and fit several sizes of MBO, Stahl, Horizon, MB and GUK slitter shafts. They simply slide on the lower shaft between the counter knives and can be used with any type of counter knives.

Sometimes an old school trick is the only way to do something if the equipment at hand is too big. Believe it or not, I’ve seen 1/16” trims run successfully on a multi-panel cover stock brochure! The secret ingredient in this instance was a piece of string and a rubber band used as a lower deflector.

Sometimes an old school trick is the only way to do something if the equipment at hand is too big. Believe it or not, I’ve seen 1/16” trims run successfully on a multi-panel cover stock brochure! The secret ingredient in this instance was a piece of string and a rubber band used as a lower deflector.

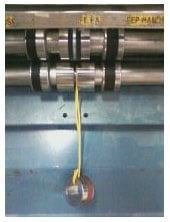

The idea is this: tie a loop of string or wire around the lower shaft. Then use a weight to keep the string in place, (photo right courtesy of Todd Summers of Nittany Valley Offset) or attach a rubber band to the string and in turn attach the rubber band to the frame to keep the string (or wire) taught. The string becomes an instant lower deflector and you probably won’t need the upper.

A word of caution about using wire: wire can score the slitter shaft and damage the counter knives. But it works really well; that’s why we see it used so often, typically a soft wire with a coating. If you can do it with string, however, you won’t risk damage.

A word of caution about using wire: wire can score the slitter shaft and damage the counter knives. But it works really well; that’s why we see it used so often, typically a soft wire with a coating. If you can do it with string, however, you won’t risk damage.

A rubber band can also be used with our lower waste stripping devices (photo left.) Tension on the waste deflector keeps it from chattering (an annoyance more than anything else) and might deflect the waste more accurately.

If you are using the string technique on a very thin trim, you probably won’t need an upper deflector in most cases. But we’re in the bindery so expect the unexpected. If you’ve got an improvised upper deflector technique for extra-thin trims, feel free to share below or use the Contact Us form to send in your idea.

As always we welcome your comments, questions and suggestions!