This is a bindery trick that is elegant in its simplicity. In other words, you really must see this at work on a folding machine, even if you never plan to use it!

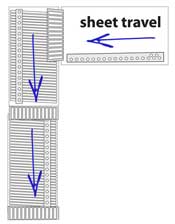

The scenario is this: you have a job that requires additional fold plates in the first right angle section. This could be due to the number of folds, extra perforating, extra creasing or other inline processing. If you can run the second right angle in tandem (inline) then it should be fairly easy (see photo at right)

The scenario is this: you have a job that requires additional fold plates in the first right angle section. This could be due to the number of folds, extra perforating, extra creasing or other inline processing. If you can run the second right angle in tandem (inline) then it should be fairly easy (see photo at right)

But space limitations might make this impossible. Print shop and bindery floors often have folders crowded together with plenty of room for conventional right-angle setups, but no room for the unconventional.

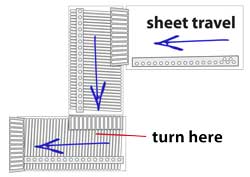

But what if you could turn the piece as it enters the right angle? (photo at left) Rotating the signature or brochure at this point would eliminate the problem. We can recall doing jobs where someone parked themself on a chair at the right angle. The folder was slowed enough so that each piece could be hand rotated. Not so bad on a few thousand pieces, but on a long run this is tedious and expensive.

But what if you could turn the piece as it enters the right angle? (photo at left) Rotating the signature or brochure at this point would eliminate the problem. We can recall doing jobs where someone parked themself on a chair at the right angle. The folder was slowed enough so that each piece could be hand rotated. Not so bad on a few thousand pieces, but on a long run this is tedious and expensive.

The video below illustrates a very simple technique to rotate the piece automatically. A single piece of strategically placed wire is attached to the frame. (right) Some experimentation with the following items is then required:

The video below illustrates a very simple technique to rotate the piece automatically. A single piece of strategically placed wire is attached to the frame. (right) Some experimentation with the following items is then required:

- Position of right angle side guide

- Machine speed and right angle speeds to control separation

- Register marbles: location and weight

- Position of wire

Once you get the right combination, you are back in the automatic folding business and the ‘impossible’ folding job is now a routine job. Thanks to Rodrigo Castellanos of Technifold Mexico for the video tip and to the folding machine operators at Offset Universal, high-volume producers of perfect bound books, where the video was filmed.

As always your comments, experiences and suggestions are welcome below, as are your video tips!

Click the Video to watch.

Problems viewing here? Go to www.youtube.com/technifoldusa