When you work with folding machines, it’s inevitable that you’ll be involved with a job that is “impossible” to run. Perhaps one fold just won’t fold consistently, or the sheet is ripping, or scuffing, or hanging up in a fold plate, and none of your regular tricks work. And because you’re the last guy in the production line, the time scheduled to produce those hundreds of thousands of pieces has evaporated and the job, which arrived in your department at 3 p.m., has to be delivered the next day. Panic sets in as you start to calculate how many people it would take to hand-fold the job overnight. Yet most folder operators figure out how to run these “impossible” jobs.

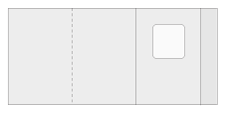

One Bindery Success reader recently emailed with the following challenge: a 6” x 13” 4-panel roll-fold self-mailer, panels 1 and 2 are 4”, one folds on a score, one on a perf; panel 3 has a cutout window (let the fun begin!) and is 4” to the score and panel 4 is a 1” flap on the outside (the icing on the cake.) [see diagram at left] The piece was die cut including scores and perforations.

One Bindery Success reader recently emailed with the following challenge: a 6” x 13” 4-panel roll-fold self-mailer, panels 1 and 2 are 4”, one folds on a score, one on a perf; panel 3 has a cutout window (let the fun begin!) and is 4” to the score and panel 4 is a 1” flap on the outside (the icing on the cake.) [see diagram at left] The piece was die cut including scores and perforations.

The problem: they could not get it to deliver without hand-sorting each and every brochure. If the piece was flipped and folded so the flap was on the bottom, the window would tear.

One of our colleagues, Paul Barrett, National Sales Technician for Tech-ni-fold Ltd. in the UK, and a bindery veteran with decades of folding machine experience, offered a unique and very unconventional solution.

Feeding as shown, fold the 1” flap first in plate #2. (You need to pack the plate to get this small a fold, itself a minor challenge.)

Feeding as shown, fold the 1” flap first in plate #2. (You need to pack the plate to get this small a fold, itself a minor challenge.)- Fold #2: go down 8” into plate #4

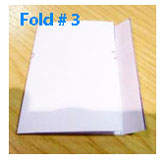

- Fold #3: go up 4” into plate #5 (on 4-plate machines, an inline setup with the right angle section is required to accomplish this fold.)

This should unfold the 1” flap and then go to the delivery table...unfolded.  The next step is the tricky part. Place the delivery wheels very close to the slitter shafts (exit rollers.) When the delivery wheels are set correctly, each sheet coming out of the exit roller will knock the now-unfolded flap back over again to complete the fold.

The next step is the tricky part. Place the delivery wheels very close to the slitter shafts (exit rollers.) When the delivery wheels are set correctly, each sheet coming out of the exit roller will knock the now-unfolded flap back over again to complete the fold.

Paul says this technique worked successfully on a very similar job he  did years ago. Another technique for tough-to-deliver folding jobs is to remove the delivery tray entirely. (This probably won’t work on the job described above.) Let the job drop directly into a box, one piece directly on top of the previous. Experiment with the size and position of the box for best results.

did years ago. Another technique for tough-to-deliver folding jobs is to remove the delivery tray entirely. (This probably won’t work on the job described above.) Let the job drop directly into a box, one piece directly on top of the previous. Experiment with the size and position of the box for best results.

A variation on this technique is to create a slide (ramp) from the exit rollers down into the box to slow the delivered piece down or to change the angle at which it drops.

I’m not sure what technique our reader used to solve his problem, but he did figure out a solution in the time it took us to reply to his email. We’d love to hear how you’ve handled such jobs. Feel free to comment below or use the Contact Us form to send your techniques to us.