The inserter pockets on saddle stitching machines are designed to run a wide range of sizes. Problems can arise when you  simultaneously run different sizes, such as a business reply card (BRC) stitched inside an 8.5 x 11” book. Getting the feeder to drop the BRC on the sword is usually simple but the trouble starts as the BRC approaches the next pocket.

simultaneously run different sizes, such as a business reply card (BRC) stitched inside an 8.5 x 11” book. Getting the feeder to drop the BRC on the sword is usually simple but the trouble starts as the BRC approaches the next pocket.

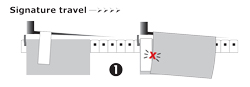

As shown in figure 1, the head of the next signature can catch the leading edge of the card, causing mis-register and probably a jam. Yes, you can time the pocket to delay the signature that’s dropping over the card. But because of the big difference in sizes between card and signature, it’s extremely difficult to get it to run consistently without jams, especially if you want to run with any decent speed.

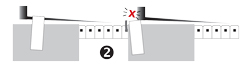

Fig. 2 illustrates another dilemma with small cards. They simply don’t weigh much, so they don’t settle squarely on the sword, nor on the signature once they slide from the sword, thus causing periodic jams. If your saddle stitcher has air lines, these will help force it down on the signature and out of harms way, but it’s not foolproof. You can also raise the sword at the next station, but there are limits to that as well. If you’ve run this type of work for any length of time, you’re probably nodding your head in agreement!

Fig. 2 illustrates another dilemma with small cards. They simply don’t weigh much, so they don’t settle squarely on the sword, nor on the signature once they slide from the sword, thus causing periodic jams. If your saddle stitcher has air lines, these will help force it down on the signature and out of harms way, but it’s not foolproof. You can also raise the sword at the next station, but there are limits to that as well. If you’ve run this type of work for any length of time, you’re probably nodding your head in agreement!

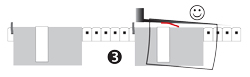

A Solution: “Float” the card by removing the sword altogether. You’ll find that you have more control in forcing the card down on the signature. Plus you can position the card so it doesn’t conflict with the signature at the next station as shown in fig. 3 by using the timing adjustments on the pocket feeder.

If you still need to jog the card to the head of the stitched book, never fear! You can rig a jogger by attaching a narrow piece of chipboard or light spring steel (e.g. steel strapping) to the sword as shown in red in Fig. 3. This requires a little finesse—you want just enough pressure to drag the card back to the head but not so much pressure that it crumples the card as it passes the jogger.

If you still need to jog the card to the head of the stitched book, never fear! You can rig a jogger by attaching a narrow piece of chipboard or light spring steel (e.g. steel strapping) to the sword as shown in red in Fig. 3. This requires a little finesse—you want just enough pressure to drag the card back to the head but not so much pressure that it crumples the card as it passes the jogger.

I successfully used this technique for years and found that it substantially reduced jam-ups and register problems. Longtime Bindery Success reader Ken Holzhauer of Arkansas reminded me of this useful tip a few years ago. Since we have lots of new online and email subscribers so I thought we’d re-visit this valuable, old-time bindery tip.

If anyone has a video of this technique in action and you don’t mind sharing, send me a note on our contact form. If the quality and content is acceptable, we’ll even pay you $50 for your time!