Here's a technique for running cover stocks 4-up on a folding machine without having to trim on your guillotine cutter.

Here's a technique for running cover stocks 4-up on a folding machine without having to trim on your guillotine cutter.

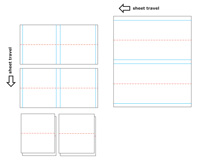

This piece is a 5 3/8 x 7 1/4" brochure, printed 4-up on the press sheet. Each brochure then gets one crease and trims all four sides. The trimmed pieces then ship flat to the customer for further processing (probably imprinting) and then final folding.

Conventionally, a job like this would involve multiple bindery machines, moving from press to die cutter (or letterpress) to guillotine. While the potential for finishing this type of job in one pass has always existed, the scoring and cutting tools available for the folding machine were not up to the task.

As you'll see in this brief bindery video tip, with the right high-end creasing and rotary cutting tools you can go direct from the press to finished product and eliminate one or more time-consuming print finishing processes. Although the layout shown is delivering flat, it can just as easily be folded without any additional work.

The fewer the touches, the higher your profit, the higher your productivity and the lower your risk for errors as the job moves through the bindery. Click the Video below to watch this techique at work on a Horizon AF566 folding machine.

We welcome your comments or suggestions below!