Anyone working with bindery equipment will probably say it's a tie between duct tape and the rubber band--both get top billing in the homegrown fix-it category. Here's one use for a rubber band that's as simple as it is effective, and is often recommended by manufacturers and experienced technicians, even with all the advancements in folding machine technology.

Anyone working with bindery equipment will probably say it's a tie between duct tape and the rubber band--both get top billing in the homegrown fix-it category. Here's one use for a rubber band that's as simple as it is effective, and is often recommended by manufacturers and experienced technicians, even with all the advancements in folding machine technology.

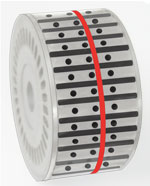

Most folders use a drum-type vacuum wheel in the feeder, whether continuous or pile fed, to pick up a single sheet and move it to the register table.

The problem: With uncoated, porous stocks, the vacuum wheel is prone to pull the occasional (or frequent) double sheet. Nothing is more deadly to bindery equipment production than machine stops.

But precise control of vacuum with light stocks at the low pressure end of the pumps range is difficult on most machines with this style feeder. Adjust the vacuum so it's feeding and all of a sudden it pulls doubles. Reduce the vacuum the tiniest bit and it stops feeding entirely. There just doesn't seem to be any middle ground working with lighter stocks in combination with powerful vacuum pumps.

The Rubber Band Solution: simply put a rubber band around the vacuum drum and re-adjust your vacuum. The rubber band reduces the sheet's surface area in contact with the vacuum wheel, in effect giving the folder operator more leeway in vacuum adjustment. If needed, experiment with a wider rubber band and you'll turn an unmanageable job into an easy one.

Be sure to keep this "classic" bindery trick in your arsenal if you encounter this problem.