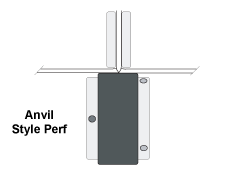

It can be a headache, but there are times when it’s necessary to run a scoring or perforating job twice through a piece of bindery equipment. Maybe you have one creasing tool available but this job calls for two or three. Perhaps it’s an equipment scheduling problem and the small folder with one scoring tool is the only one available that day. The headache usually starts with the second pass through the machine, when the operator discovers the entire first pass didn’t register, or is in the wrong position, or is crooked. Worse yet, a customer discovers the problem!