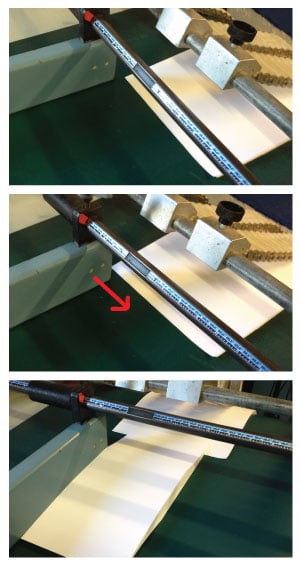

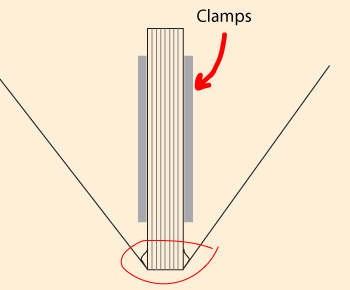

The folding machine operators I’ve met would never let a little cut on their fingers keep them sidelined. You’ll hear, “Ah…it’s just a flesh wound. A little duct tape will fix that.” After working with rotary cutting or perforating blades for many years you’d think an experienced folder operator would never get cut. Yet all it takes is a split second of carelessness, mishandling, or reaching into the folder too quickly to clear a paper jam and you’ve got a painful cut. Heck, we've had people at trade shows cut themselves while admiring our uniquely constructed durable blades! (Don't worry, we'll have gloves on hand at Graph Expo in Orlando, FL at Booth #2611.)