The cold dry months of winter always seem to set the stage for an increase in printing and print finishing problems. All the printing paper reps I know brace themselves for an onslaught of complaints. Static, fiber cracking, and coating problems are typical. But is winter really such a dry time?

We’re taught that proper Relative Humidity (RH) is a critical factor in the performance of paper. It is a proven fact that decreased RH has a negative impact on fold quality. The lower the RH, the more the paper will crack, as shown in these photos, right, in a Sappi Paper report, Folding and Creasing, available here. In folding tests, one batch of paper was acclimated at 25% RH and another at 50% RH. Then both were folded on a regular folding machine. The photos say it better than I can. RH is important.

We’re taught that proper Relative Humidity (RH) is a critical factor in the performance of paper. It is a proven fact that decreased RH has a negative impact on fold quality. The lower the RH, the more the paper will crack, as shown in these photos, right, in a Sappi Paper report, Folding and Creasing, available here. In folding tests, one batch of paper was acclimated at 25% RH and another at 50% RH. Then both were folded on a regular folding machine. The photos say it better than I can. RH is important.

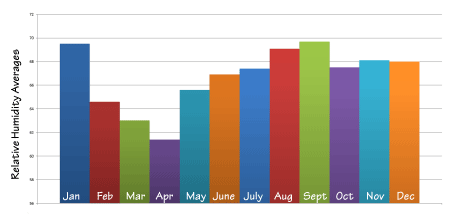

So my inner nerd prompted me to go deeper and chart some historical records of average relative humidity around the US. The sampling includes Atlanta, Austin, Baltimore, Birmingham, Boston, Buffalo, Charlotte, Chicago, Washington DC, and Denver. The data, compiled from NOAA data at currentresults.com, covers a 30-year period ending in 1991.

You might be surprised to see that the average relative humidity going into the winter months is, well, about average. (Chart lower right.) There is a 12 point drop going into October, after 6 months of steadily increasing relative humidity. But it’s not quite what I expected.

So what’s this mean? If you go by this data, you’d think there would be fewer problems in the winter months since RH is higher, on average. April should be the worst month for humidity problems in the pressroom and bindery, but it’s not, at least in my experience.

So what’s this mean? If you go by this data, you’d think there would be fewer problems in the winter months since RH is higher, on average. April should be the worst month for humidity problems in the pressroom and bindery, but it’s not, at least in my experience.

The reason is that this RH data is only half of the story. The other half of the story happens once you get inside the press room or bindery. Once inside, your temperature and RH are very different. It’s simple once you understand the concept of relative and absolute humidity.

Relative humidity is the ratio of partial water vapor pressure to the saturation vapor pressure at a given temperature. If that makes your head hurt, think of it as the amount of water vapor actually present in the air divided by how much water vapor it could hold at that temperature, expressed as a percentage. Absolute humidity is the mass of water vapor present in a volume of air space usually expressed as grams per cubic meter (g/m3). Most importantly, the maximum absolute humidity changes with temperature.

For instance, at 32˚ F, a cubic meter of air can only "hold" 4.85 grams of water vapor. At 68˚ F the air can hold 17.24 g/m3. At 86˚ F, it can hold 30.2 grams. (The word “hold” will probably make scientists cringe but it seems to be the easiest way for most of us to understand the concept.) Thus during cold winter months there is far less water vapor per cubic meter than in summer.

But if the all-important RH is nearly the same year round, why are there more problems in winter? The answer is simple.

Let's say it's 75% RH and 32˚ F. That means the air has .75 X 4.85 = 3.64 g/m3. (Remember, 4.85 is the maximum it can hold at 32˚ F.) Now let’s go inside where it's heated to 68˚ F. At 68˚ F the air can hold 17.24 g/m3. But the environmental air we are bringing in from the outside only has 3.64 g/m3. This means our indoor RH is 3.64 ÷ 17.24 = .21 or 21%. Unless the indoor air is humidified, we now have a problem with very low RH. It should be in the neighborhood of 50%. In summer the opposite is true. We’re bringing warm air with high water vapor content into a much colder environment. The indoor air is immediately saturated so the RH can be extremely high.

Of course my explanation is simplified for the sake of clarity for all of us non-scientists. Weather phenomena get quite complicated! The point is that if you find that your print finishing results have changed for no apparent reason, and there was a significant change in the weather, it’s possible that RH is behind the change. Winter is indeed a dry time.

Paper will grow or shrink and change its behavior with very small changes in moisture content, which is directly related to RH. Even if you don’t control the overall climate in your shop, don’t forget to look at the things you can change.

I recall running jobs on a Bobst die cutter for days at a time. Two days might go by without any need for adjustment or patching up spots that weren’t cutting. Then the next morning quite a few spots needed patching, or the units seemed slightly out of register. Perhaps you’re folding paper one day and the next you find it needs to be creased. In both cases, RH variations could be the problem. The solution is a small adjustment or change in procedure.

If you’re fortunate to work in true, climate-controlled print finishing environment, you won’t have so many of these problems. Otherwise, when mysterious bindery problems occur, take comfort in the fact you’re not crazy. It could be a little bit of water vapor messing with your head.