One baffling problem encountered by many folding machine operators was recently brought to our attention by a Bindery Success™ reader. Here’s the scenario. First, you set the fold rollers pressure (roller gap) for the job you’re running, just as you’ve successfully done a thousand times before. At some point during the run, the fold starts to vary, or perhaps the trim or perforation starts to move around. You double check the fold roller pressures only to find one or more of them too loose, as if the folder were changing fold roller pressure on its own.

So you reset the rollers and all is well until the same problem re-appears a little later. What the heck is going on? There are several common things that could cause an un-commanded change in your roller settings. Two of these can be easily fixed by operators while the remaining causes could require a technician.

So you reset the rollers and all is well until the same problem re-appears a little later. What the heck is going on? There are several common things that could cause an un-commanded change in your roller settings. Two of these can be easily fixed by operators while the remaining causes could require a technician.

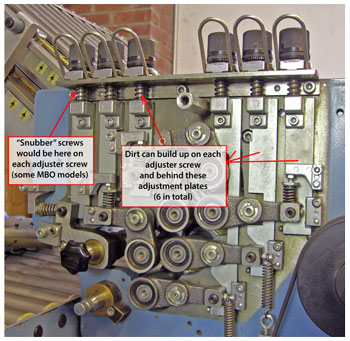

First, let’s look at the easy fixes. On some MBO machines, there is a set screw that acts as a mechanical “snubber” of sorts. In the case of the MBO machine, the snubber screw will prevent the roller adjustment from rotating while running, yet still allows you to turn the knob as needed to adjust fold roller pressure manually.

Our MBO B123 doesn’t have one, but the photo indicates where it would be located on those machines that are so equipped. If you find your roller pressures changing as you run, this should be the first thing to check. Simply remove the side covers to see if you have this feature. If so, then tighten the screw slightly. If it’s too tight you won’t be able to adjust pressure manually. If it’s too loose you’ll continue to lose pressure as the folder runs. Find that sweet spot.

If your MBO folding machine has this adjustment but you’re not sure if the roller pressure is changing, it’s easy to find out. Simply put a witness mark running from the black adjuster knob to the base below the knob. This will indicate whether or not the adjuster knob is moving while you’re running. If so, you need to tighten the screw until the movement stops.

The next item on our list is Sticky Adjuster Mechanisms. Accumulations of dirt and paper dust can prevent the adjusters from operating freely and properly. (arrows in photo upper right) In extreme cases it’s possible for dirt buildup to keep a roller open far beyond the gap to which it was originally set. In other words, you might open the gap sets to insert your sheets of paper and the gap set doesn’t close all the way. Or maybe it closes very slowly as you are running. A jam or double sheet could push it back open and the dirt will keep it there.

If you suspect dirt is the culprit, give this area a thorough but careful cleaning. If lubricant is required, be sure the correct lubricant is added according to directions for your folding machine.

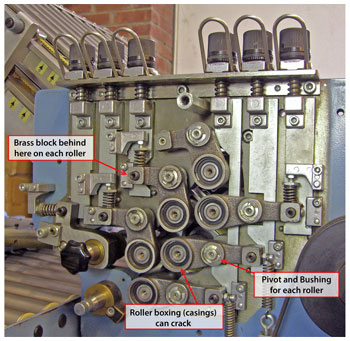

Now we come to Mechanical Wear and Tear. As you can see in the photo, every roller system has plenty of mechanical components. Even a single worn item can lead to fold roller pressures straying from where you think you set them. Although fold roller systems will vary, the basic concept and operation is all very similar.

Now we come to Mechanical Wear and Tear. As you can see in the photo, every roller system has plenty of mechanical components. Even a single worn item can lead to fold roller pressures straying from where you think you set them. Although fold roller systems will vary, the basic concept and operation is all very similar.

On most MBO folders there is a brass block on each roller adjuster which needs to be replaced when rollers are replaced. Baumfolder and Stahl machines don’t have these.

If the roller boxings (also called housings or casings) are cracked, they will need to be replaced.

The roll pivot point may have a bushing or bearing, also subject to wear and replacement. The roll pivot itself (‘eccentrics’ on the older Baumfolders) may need replacement.

Fold rollers will have bushings and/or bearings at each end of the rollers which periodically need replacing. The fold roller journals themselves (the ends of the fold roller core itself) are also subject to wear. Generally the roller bushings/bearings will wear first but on an older machine, or on a poorly maintained machine, it’s possible the roller cores themselves need replacing and not just re-covering.

The first two items I mentioned are easy to check and fix yourself. When it comes to the mechanical items, it’s best to hire a mechanic experienced on your model of folding machine.

The bottom line is that if you’re plagued with a folding machine that has a mind of its own, (aside from its normal automated features,) it’s not really a mystery and the fixes can be fairly simple.

Thanks to Dave Double of Double Equipment for his contributions to this article!