A Bindery Success™ subscriber recently emailed to talk about an issue he was having with perforating on their folding machine. As with most post-press problems, the more we dug into it, the more we had to peel back layers. In this case the problem which generated  the inquiry is that perforator blades are wearing out too fast for the boss’ liking.

the inquiry is that perforator blades are wearing out too fast for the boss’ liking.

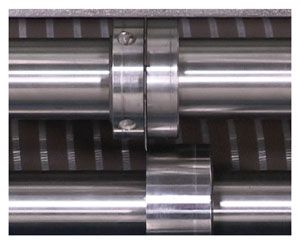

Evidently there is an internal debate at this particular shop on the merits of two different methods of rotary perfing. The ‘conventional’ method, especially on folding machines, is to use a single-bevel perf blade on the upper shaft that butts against a steel counter knife on the lower shaft (photo at right). Some of the counter knives have grooves in them. The other method (our preferred method for micro perforating) is the anvil method in which a perf blade actually rides on top of an anvil.

It sounds like the ongoing argument in their shop is an either/or dispute. Our reader has successfully used anvil perfs in another shop and believes that will solve the problem. His folding machine technician (and his boss) believe that the conventional style is the right way to perf and simply won’t consider another way.

To settle their specific dispute we would need more details, but our reader’s dilemma raises some important points about perforating paper. So this is where the peeling begins.

To settle their specific dispute we would need more details, but our reader’s dilemma raises some important points about perforating paper. So this is where the peeling begins.

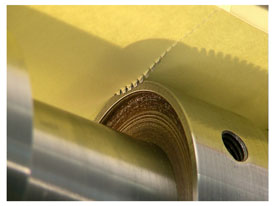

We believe there is a time and a place for each style. The conventional rotary tools are great for signature work or jobs where appearance isn’t an issue. In signature work we’re often cutting through a lot of paper to allow air to escape and the large teeth on these tools excel at punching through multiple sheets of paper. The down side is that such perfs are rough in appearance. The single bevel blades also break easily, especially the very fine micro perf blades. The ridges produced by this type of device (photo at left) can also interfere with equipment should the perfed sheet be run in subsequent operations.

If appearance matters, or if the perfed sheet will be run through copiers, laser printers, digital presses, mailing machines, or finishing equipment, then you’ll need to move to a premium perforator such as the Technifold Micro Perforator. This anvil-style tool allows the sheets to remain much flatter. It closely duplicates the action you get on a die cutter, cylinder press, or letterpress. The double bevel perf blades used here are also much stronger and can be manufactured with finer perforations than their single-bevel cousins.

Let’s return to the original problem, which raises questions.

Whenever you’re perfing you have to select the right tool based on the desired end result and materials involved. Whichever style of perforating you require, here are seven basic perforating tips for achieving high-end results.

1) Always set the shaft gap correctly (also called pressure or pitch). Anvil style perforating works best when you use the minimum pressure required to cleanly perf the sheet from lead edge to tail.

1) Always set the shaft gap correctly (also called pressure or pitch). Anvil style perforating works best when you use the minimum pressure required to cleanly perf the sheet from lead edge to tail.

2) Be sure the bushings, bearings, couplings and shafts on your folding or scoring machine are in good condition. Excess play in any of these will affect blade life and performance.

3) Keep your counter knives sharp. Many operators don’t realize this has to be done, let alone how important it is. When you start running a fresh, sharp perf blade against a dull counter knife, you soon have a dull perf blade. (The same holds true for cutting knives against a dull counter knife.) You  can even try pulling the blade away from the counter knife ever so slightly. This could make it worse but if it works, your blade will last a little longer.

can even try pulling the blade away from the counter knife ever so slightly. This could make it worse but if it works, your blade will last a little longer.

4) Keep the tool components clean. Dirt on the blade holder (photos at right) or on the blade itself will prevent the blade from being seated flat in the holder. As it rotates it will then have small wobble which in turn will wear out the blade prematurely.

5) Use high quality parts. If the tools wobble on the shaft, blades and counter knives will wear quickly. Tight tolerance tools, made well, will improve your results. Lower quality steel also tends to rust and corrode which will affect performance if the blades don’t seat properly.

6) Test your perforation through its final use. That’s the only way to ensure you’ve selected the right perforation for the job at hand. For example, if the sheet will be run through a laser printer and then  mailed, do that. Or have your customer do it for you and give you the OK.

mailed, do that. Or have your customer do it for you and give you the OK.

7) Keep a log. Keep notes of the setups you use for each job. You don’t want to re-invent the wheel every time you set up a job. If your job ticket system doesn’t allow for this, keep your own notebook. Or make good use of that smart phone if you don’t like the old fashion pen and paper.

One or more of these suggestions just might solve the problem. In the meantime feel free to add your own suggestions or experiences below.

If you’d like to see what kind of results you can get from an anvil-style perforator on your folding machine, go here to request a free sample kit.