When I first saw this question I wondered why a folding machine operator would even ask it. It goes something like, “When I load my folder, where should the guide and gripper edges go?” Or, “Does it matter which way I load paper into a folding machine?” I reminded myself there is a first time for any question, especially learning a complicated subject like bindery work.

Also it’s not such a crazy question if a novice sees a veteran loading the folder the “wrong” way. That’s one way to make things clear as mud to the novice.

Although it’s a simple question to answer, there are at least four things to consider.

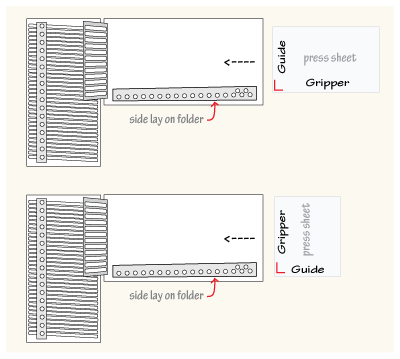

1) If you have the original guide and gripper on the sheet, always load it to feed as shown in the diagram at right. One edge will be against the folder side lay. The other edge will be the lead edge going to the fold plates. So there. That’s the simple, direct answer.

1) If you have the original guide and gripper on the sheet, always load it to feed as shown in the diagram at right. One edge will be against the folder side lay. The other edge will be the lead edge going to the fold plates. So there. That’s the simple, direct answer.

We often keep the guide and gripper edges when we run signatures. Register is better and they trim later during saddle stitching or perfect binding.

Pay attention to the guide and gripper to maintain quality. Most readers might say, “Well, that’s obvious and goes without saying.” The fact is it needs saying. I’ve seen experienced operators load press sheets the wrong way and insist it won’t matter.

Why would they do something like this? Usually it’s to “save time” by not changing a couple of fold plates and fold roller settings. Or perhaps they don’t want to turn the signatures over to load them the right way. Their reasoning is, “This paper is good; it doesn’t vary that much.” Of course if they run into a crossover (lineup) it will never line up consistently. If they’re doing book work with folios (page numbers), the folios will bounce all over the place.

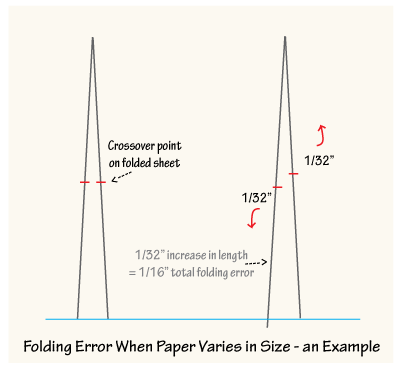

When you run sheeted paper, it will vary in size. Don’t forget that variations in paper size will double the error in the folding process when you run opposite the side guide and/or gripper. A 1/32” difference in size means 1/16” difference in the crossover. (Diagram at right.)

When you run sheeted paper, it will vary in size. Don’t forget that variations in paper size will double the error in the folding process when you run opposite the side guide and/or gripper. A 1/32” difference in size means 1/16” difference in the crossover. (Diagram at right.)

The trap that snares folder operators is that the first couple hundred sheets might be perfect. Later they get to the next ream or a different batch of paper and all the adjustments have to be re-done. Trying to chase paper with folder adjustments is a losing and pointless battle. After struggling awhile, they take time to unload and re-set the machine. The operator who thought he or she was saving time by not using the guide and gripper thus wastes time.

When you run with the guide and gripper, your registration will be as good as the press, or close to it. There will be fewer problems and adjustments required during the run. This get you as close to a “set it and forget it” scenario as you’re likely to ever find.

If you do a lot of signature work, it pays to be on good terms with your press department! You should get all your signatures delivered to the bindery so nothing needs to be turned over manually. And you don’t want to re-do any folder setup because the side guide keeps changing from form to form.

2) If the imposition is such that you must run opposite a guide or a gripper, then it pays to guillotine trim that side. This way you maintain good register and avoid the problems just described.

3) Consider curl if the job you’re folding is guillotine trimmed, (no original guide and gripper). It’s another factor that can influence how you’ll load your folder. If you’re running a standard brochure you probably have a routine way of loading the sheet to use specific fold plates. Yet if the job has a severe curl on the lead edge, it could cause feeding problems. Thus you might want to think about loading it the opposite way and use different fold plates.

4) If you are folding a cover weight paper, you may need to load it a different way than you would a text-weight paper. For instance, you might normally fold a 4 page 70# text brochure in plate #1. So you load it to run that way. But if you’re running a 4 page brochure on 100# cover, you’re better off doing it in plate #2 or #4…the “bottom” fold plates. This changes how you load the sheet. (We talk about why this is so in this related article.)

Although the answer to the original question is simple, you might see some operators complicate matters by taking an ‘easy’ way out. Of course the easiest way is to do it the right way.

If you’re new to print finishing and this article left you with more questions than ever, let us know in the comments box below or use the Contact Us form. Be sure to share it with your colleagues and friends using the social buttons.