Although this tip might raise more questions than it answers, the real value lies in the fact that it reinforces creative thinking in the face of an unusual bindery problem. So while we might never be faced with this exact problem, it could inspire a solution for whatever post-press problem you’re facing today.

Thanks to Nathan McCollim, operator of a Muller Martini Star Plus perfect binding system, for submitting this interesting tip. The shop he works for produces books for schools, and many of these books have perforated pages so that students can tear them out and easily work on the single page.

But it’s not so easy for the younger children to tear out the pages. Also, distributing and collecting an entire book is more cumbersome for teachers than working with individual sheets.

But it’s not so easy for the younger children to tear out the pages. Also, distributing and collecting an entire book is more cumbersome for teachers than working with individual sheets.

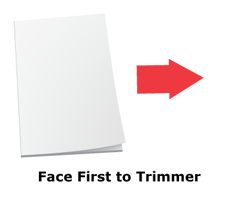

Faced with this alternative demand for the same product but in a different format, the shop started trimming the spines from books in inventory. (illustration at left)The trimmed books are then shrink wrapped and shipped as collated sets to the teachers. Other customers prefer to receive spiral bound books of the same content. In those cases the spines are trimmed so the pages can be hole-punched and spiral bound.

Spine trimming solved the customer demand problem for this particular company. But a new problem surfaced during the trimming operation.

Initially, McCollim says, they ran the books into the trimmer with the open face at the leading edge. (Illustration at right) Normally the spine leads the way so reversing the direction to trim the opposite side makes sense at first glance. But this travel direction meant that pages would occasionally flare open and jam the trimmer. It also caused a waste removal problem. The stiff, glued spines that were being trimmed off didn’t easily fall into the waste collection funnel.

Initially, McCollim says, they ran the books into the trimmer with the open face at the leading edge. (Illustration at right) Normally the spine leads the way so reversing the direction to trim the opposite side makes sense at first glance. But this travel direction meant that pages would occasionally flare open and jam the trimmer. It also caused a waste removal problem. The stiff, glued spines that were being trimmed off didn’t easily fall into the waste collection funnel.

Paper jams were frequent enough that they stationed a worker at the Muller Star Plus whose sole job was to remove jams and keep the waste flowing. The machine shutdowns from jams wasted a huge amount of production time and also ruined as much as 10% of the job.

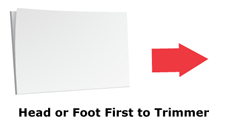

His solution was simple. Rotate the book 90 degrees to feed into the trimmer foot or head first. (Illustration, right) Then use the side knife instead of the face trim knife to remove the  spine. The glued spine prevented pages from flaring as frequently and made handling easier. The new position of the spine also meant the trim waste was oriented in such a way that it didn’t jam at the waste collection funnel.

spine. The glued spine prevented pages from flaring as frequently and made handling easier. The new position of the spine also meant the trim waste was oriented in such a way that it didn’t jam at the waste collection funnel.

McCollim also kept records on both methods to track spoilage. The results:

Using the ‘conventional’ method of feeding the book face-first into the trimmer:

Job 1- 6,000 books spine cut with 500 books lost

Job 2- 6,000 books spine cut with 600 books lost

Using new method, feeding at a right angle:

Job 1- 5,240 books spine cut with 33 books lost

Job 2- 611 books spine cut with 15 books lost

Job 3- 2,311 books spine cut with 63 books lost

Job 4- 60,000 books spine cut with 200 books lost

As you can see, this new technique reduced spoilage from 10% to an average of 1.5%. This is significant, especially when you consider that the spoilage in this case is actually finished product, with tremendous value already built in. Put another way, a wasted book costs far more than a wasted signature. Since his initial experiment, they have trimmed the spines of another couple of hundred thousand books, with similarly low spoilage rates.

Will you face this problem in your shop? My guess is probably not. But there are plenty of other possible bindery challenges that could come your way. When that happens, take a breather and try looking at the problem from a new perspective. A little brainstorming and lots of “What if…” questions can go a long way!

Thanks Nathan for your tip! Remember, if you have a tip to share, you can earn $100 for a basic tip up to $250 for a tip with videos and/or photos. Use the Contact Us form to email your idea. If we haven’t used it and it’s a good fit for our readers, we’ll feature it here.

As always, we welcome your experiences, suggestions and comments below.