Here's a question we hear frequently, especially from folder operators new to running cover stocks on folding machines...."Even though I've scored it, the cover stock I'm running still cracks when I run it through the folder; what can I do?"

Here's a question we hear frequently, especially from folder operators new to running cover stocks on folding machines...."Even though I've scored it, the cover stock I'm running still cracks when I run it through the folder; what can I do?"

First, check the score. When using a Tri-Creaser try different settings until satisfied with the hand fold. If it was scored offline or with another tool, this tip still helps! If you can fold it by hand and it looks good, we believe you can get it through the folding machine without making it look worse. Yes, many digital or heat-set web jobs, and certain paper stocks will crack if you just look at them. In some cases even the best die score doesn't eliminate fiber cracking. Even so, this technique will minimize the damage and can turn a reject-quality job into an acceptable one.

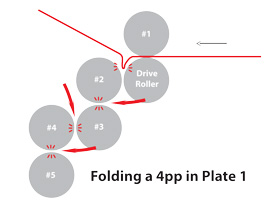

We'll use a 4pp, 1-fold piece as an example. The common way to fold this is in fold plate #1; that's how we were all trained. Fold roller caliper 1 has one sheet of stock, 2 through 5 have 2 sheets. All well and good for text stock. As shown in the fold roller diagram above, the sheet is driven into plate 1, it buckles (folds) then travels through the remaing rollers with fold plates closed off. This means you have 4 pinch points where pressure and bending forces are applied to the folded spine after it is folded. That's 4 opportunities to make it crack.

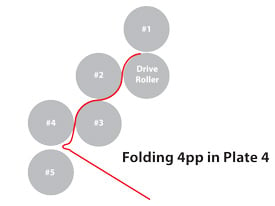

A Solution: use fold plate #4 to make the fold as shown in the next drawing. Then reset the calipers like this...1 sheet in calipers 1-4 and 3 sheets in caliper 5 instead of the normal 2. Remember that folding machine rollers drive the sheet, so we don't really need any pressure on fold roller #5.

A Solution: use fold plate #4 to make the fold as shown in the next drawing. Then reset the calipers like this...1 sheet in calipers 1-4 and 3 sheets in caliper 5 instead of the normal 2. Remember that folding machine rollers drive the sheet, so we don't really need any pressure on fold roller #5.

The end result is we've reduced the 4 pinch points from 4 to 0, and you now stand a much better chance of getting that delicate cover stock folded without any cracking. You can use this same principle when folding a 6pp on cover stock. Use the "bottom" fold plates 2 and 4 or 3 and 4 to make your 2 folds. Then remove all pressure from fold roller 5 with an extra sheet and use minimum pressure on all other fold rollers.