This week we will discuss folding machine tips for perforating to achieve high quality 16 page signatures (or any signature that uses a perf, including 32pp sigs.)

If perforating signatures is new to you, you might run across three common problems.

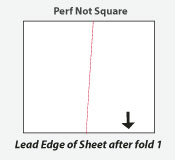

- The perf is not square to the sheet

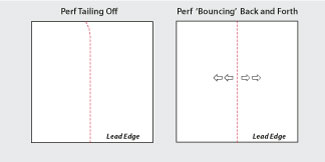

- The perf 'tails off' or curves

- The perf seems to bounce back and forth, seeming to change position side to side

Always check basic items first: fold roller calipers for correct number of sheets, fold roller and slitter shaft tension, side guide is square for sheet, and feeding and register is good.

When it all looks perfect but your perforation is still crooked (but straight,) here's a fast and easy technique: drop (or raise) one side of an unused fold plate on the side of the sheet that needs to be slowed.

When it all looks perfect but your perforation is still crooked (but straight,) here's a fast and easy technique: drop (or raise) one side of an unused fold plate on the side of the sheet that needs to be slowed.

In the example at left, the left side is traveling faster than the right through the fold rollers (hence the perf angled to the right) so you need to slow the left side. If folding takes place in plate no. 1, then you can pull out the left side of fold plate 2, 3 or 4 a small amount, say 1/16" to start. (If folding in plate no. 2, then only plates 3 or 4 can be adjusted.)

Make small adjustments, checking the sheet after each adjustment. You may find that making smaller adjustments to 2 or 3 plates gives more consistent results than making one large adjustment to one plate.

Problem #2, the perforation ‘tailing off' as shown, has a counter-intuitive solution.  Use fewer pull out wheels (gripper rollers) on the slitter shaft-or use none at all on top with just a few on the bottom to support the sheet as it exits the slitter shafts. Also check that the perf blade is running in the correct direction if it has angled teeth. Usually the bevel side of the perf blade faces the next fold section. Ensure that the perf blade holder is mounted on the shaft correctly, so that shaft rotation doesn't loosen the collar.

Use fewer pull out wheels (gripper rollers) on the slitter shaft-or use none at all on top with just a few on the bottom to support the sheet as it exits the slitter shafts. Also check that the perf blade is running in the correct direction if it has angled teeth. Usually the bevel side of the perf blade faces the next fold section. Ensure that the perf blade holder is mounted on the shaft correctly, so that shaft rotation doesn't loosen the collar.

Problem #3 is likely the result of an inconsistent, out-of-square fold. Note: if you set the job to fold at a slight angle to compensate for a crooked sheet or crooked printing, that's OK as long as every sheet comes out the same. It's the bouncing around that will give you fits with perforating.

Folding machine mis-register like this has many possible causes:

- poor feeding

- the side lay being too far away from the sheet

- side guide marbles too heavy or too light

- crooked paper

- static

- rollers poorly set

- paper curl

For now, the point is to make sure you've got the folding nailed first, before you go on a troubleshooting mission to nowhere.

We've seen operators waste loads of time trying to fix a perf that was ‘bouncing' when the real culprit was an inconsistent fold, usually requiring a simple fix.

Be Sure to Check Out Our Full Line of Micro Perforating Tools, Multi-Tools, and CP Applicators which offer a tremendous amount of variety and versatility in for any Micro Perforating job.