Most folding machine operators are familiar with the use of marks to aid in setting up any given folding job. Depending on your model of folding machine, it’s likely loaded with marks, indicators, dials and rulers to make it easier to set up. You probably have a lot of home-made marks of your own. Those of you with newer computer controlled automatic folders have it even better. You can dial up the exact same settings again and again with the push of a button.

For those with the pre-computer folders, there is a way to reduce setup time and increase accuracy. There is a concept that is popular in other industries such as woodworking and metalworking which can easily be applied to your folder. I’m talking about the use of jigs, gauges or templates to reduce setup times to a bare minimum and to reduce waste to as close to zero as possible.

I frequently used jigs in woodworking, a hobby, and I also used them to speed up hand-assembly projects in the bindery. Yet I never thought to transfer the concept to my work on folding machines. If I had it to do over again, I would make it a priority!

If this all sounds very “Lean” in nature, well, it is. In Setup Reduction for Printers, Malcolm Keif and Kevin Cooper review the concept of Lean as it applies to printing and print finishing operations. The goal of Lean is to eliminate anything that is waste, which translates to anything that the customer isn’t willing to pay for. This is overly simplistic but in short, the customer is paying only for product. Everything else is ‘waste’ and should be eliminated. Setup time is considered waste and the book discusses many approaches to reducing setup times.

Your company may or may not embrace Lean practices. It doesn’t matter. If you are an operator, supervisor, manager or owner, it’s in your best interest to always search for ways to become more valuable today than you were yesterday. A Lean state of mind will help you do just that.

Jigs and templates are anything that is used to position a variable adjustment on your machine. The authors use the illustration of an operator setting up a pile feeder and delivery by grabbing a handful of sheets to set the in-feed and delivery guides. That’s a very basic jig.

Of course the use of jigs and gauges only makes sense on repeat jobs since it takes time to create a useful jig. How do you determine what jigs or templates to create? In the spirit of Lean, the creation of such jigs is the result of asking a lot of difficult questions. Maybe start by asking “How can I reduce my folding machine setup waste to zero sheets?” Or to put it another, way, can you set up your folder so the first sheet in the delivery is perfect? If not, why not?

I suspect most operators will start to hem and haw nervously about now. After all, its ‘customary’ to have a certain amount of paper wasted and time wasted in setting up a folding machine or any other piece of bindery equipment. I say let’s toss customary out the window.

Even if your equipment is somewhat dated, you can start asking questions. The answers can give you setup reduction ideas you might not have ever considered before.

Let’s stick with the folding machine example. An easy and common setup is the letter fold on a book weight, 8.5x11” paper. On a simple folder you have the infeed guides, a vacuum or friction feeder, at least 2 fold plates, and delivery tray to set up. Pretty easy and it doesn’t take too long, right? I bet if you’re like most folks, you or your operators get it set pretty closely and then fiddle a bit with the fold plates to dial it in.

But what if you could set it up so that the first sheet was perfect? How much time would that save you over the course of a year? If you do a letter fold job 100 times a year, and you save just 5 minutes of setup each time, you’ve saved 500 minutes or just over 8 hours.

But what if you could set it up so that the first sheet was perfect? How much time would that save you over the course of a year? If you do a letter fold job 100 times a year, and you save just 5 minutes of setup each time, you’ve saved 500 minutes or just over 8 hours.

How can a jig or a gauge do this? Let’s look at the fold plates. Most machines have adequate markings and will get you pretty close, but a little fine tuning is almost always required. A jig will eliminate this ‘fine tuning’ step.

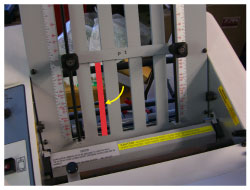

Set up the machine so you have it folding perfectly. Now cut a wooden stick exactly to size to use as a gauge in each of the two fold plates you are using, as shown in the photo above. (A used plastic cutting stick from a guillotine cutter might even be better.) It may take a bit of re-cutting. Once you have the perfect fit, you can use these to dial in both fold plates before you ever run a sheet. The first sheet out should be perfectly folded, without any fine tuning. (The jigs will likely be slightly different for various weights of paper.)

Let’s look at setting up a 16-page right-angle signature. To what else could a jig or gauge be applied? What about infeed guides (continuous or pile feed), perforating blades, cross carriers, or cutting knives? If you put your mind to it, you can probably come up with some home-made ways to precisely and repeatedly position everything so as to produce a perfectly folded, perfed and trimmed sheet starting with sheet #1, and to do it faster than ever.

Think about all the little fine-tuning adjustments you make setting up such a signature. I just listed four things. Multiply that by several minutes of setup time each and you see that time savings can be significant when repeated over the course of a year.

Before you say “But, that’s impossible…” ask yourself, “Why not?” It will raise a lot of questions. Turn them into “what if” questions and you may be surprised at the answers you come up with. For a little outside-the-box thinking, ask the questions of people who know nothing about your machine. It may not be possible to achieve perfection, but if you continuously improve your setup times, you continuously become more valuable.

Look for more on this subject soon. If you’re using jigs, templates or gauges on your bindery equipment and would like to share, let me know using the Contact Us form. Or feel free to share your comments, suggestions and ideas below!