I hope so! Some things are timeless, especially when we talk about work habits; they don’t really have an expiration date. As long as guillotine cutter technology is around it seems that its venerable work habits should tag along. Even in this era of evolving bindery automation, guillotine cutters are still at the heart of most print finishing and bindery operations.

We know that poor cutting will affect any subsequent operation. Folding a poorly cut job is difficult or even impossible. Skewed cutting or cutting with a dull knife causes problems on the press, copier or digital printer. Badly cut stock will cause problems feeding on any type of office bindery equipment. If  cutting is the last step before it goes to the customer and they notice an uneven border or a skewed image, it’s likely the job will be rejected.

cutting is the last step before it goes to the customer and they notice an uneven border or a skewed image, it’s likely the job will be rejected.

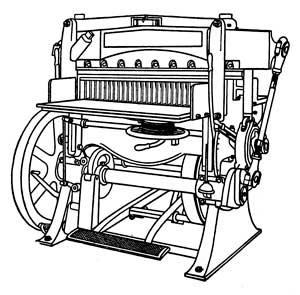

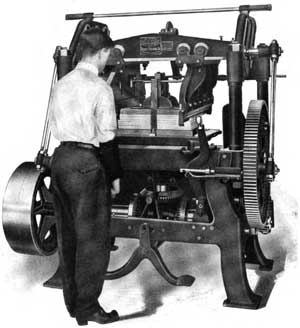

In his book Paper Cutting Machines, Niel Gray discusses the problems of paper cutting. He includes some simple but solid suggestions to improve the work routine in order to become more productive. Surprisingly, these suggestions were published nearly one hundred years ago, in 1918. Yet these are four solid tips for newcomers to cutting as well as good reminders to industry veterans, or for supervisors responsible for training new bindery workers.

Good judgment is required to determine the proper height of a pile to cut. This will often depend upon how much can be grasped each time with the hands and put into place in good order. Time may be lost and sheets wasted trying to fill up the capacity of the machine; smaller piles and more of them may sometimes be a more economical method.

Removal of cut stock and waste disposal. Of vital importance to the cutter operator's speed is an orderly procedure in removing cut paper from the machine and stacking it for transfer to other departments. Convenient tables with ample surface, or bindery trucks, will aid in eliminating unnecessary motions and steps. Each stock pile should be neatly stacked to prevent its capsizing, and should be clearly labeled with the name and the number of the job for which it has been cut.

Each cutter should be equipped with a large container for waste and trimmings. Throwing waste on the floor is unsightly, is dangerous to the operator's footing, and constitutes a fire hazard. It should be neither practiced nor allowed.

Many plants in metropolitan areas bale their waste and sell it. This waste is particularly valuable if it is quantities which can be sorted as it is cut. In addition, larger plants often install low pressure vacuum tubes into which the waste may be thrown. The cuttings travel through the tubes from all machines to a central point for baling.

To improve the accuracy of cutting. Cutting sheets accurately to a minimum tolerance requires first, a sharp knife, second, correct clamp pressure, and third, a lift of such thickness as to be cut easily without strain by the machine in use. Each of these factors affects the amount of "draw” which the paper undergoes.

Draw is the condition wherein the uppermost sheets in the pile being cut are pulled away from the back guide toward the operator due to the pressure of the knife forcing its way through the pile. The result is that these top sheets will be cut smaller than sheets lower in the pile.”

Let’s see now, he’s covered:

Let’s see now, he’s covered:

- superior intelligence

- good judgement

- orderly procedure

- good equipment

These 100-year-old principles don’t seem so outdated to me. No single piece of bindery equipment operates alone, in a vacuum. There are usually several related components required for the successful completion of any given bindery project. Your cutting system practices can affect the entire post-press operation.

If you’re a cutter operator, it pays to be mindful of the importance of your work. If you run other bindery equipment, it pays to be mindful of the quality of the cut sheets arriving at your machine. It can make or break your production for the day and save you troubleshooting time later on.

Whether you’re a novice or a veteran, these “vintage” concepts and problems should give you some things to think about in your modern post-press department. As Aleksandr Solzhenitsyn said, "I leaf through the ancient philosophers and find my newest discoveries there."

And whatever you do, make sure you’re friends with your cutter operator! Feel free to share your cutting stories or tips below.